Functional Safety

Achieving functional safety is a critical consideration for any organisation operating in high-risk, mission-critical sectors such as Automotive, Healthcare Life & Science, Industry 4.0, Defence & Aerospace and Robotics, as it involves adhering to standards and processes that ensure safety functions are performed correctly.

Functional safety redefined – innovative solutions for a safer tomorrow

At Spyrosoft, we understand the crucial need for robust functional safety practices across these industries. Our team of experienced experts leverages their deep knowledge of international standards like ISO 26262, IEC 62304, IEC 61508 or IEC 62443 to deliver comprehensive functional safety solutions. Obtaining functional safety certification is essential, and it should be conducted by independent organisations with technical expertise. Functional safety pre-certification programs play a vital role in ensuring safety in systems involving electronics and software.

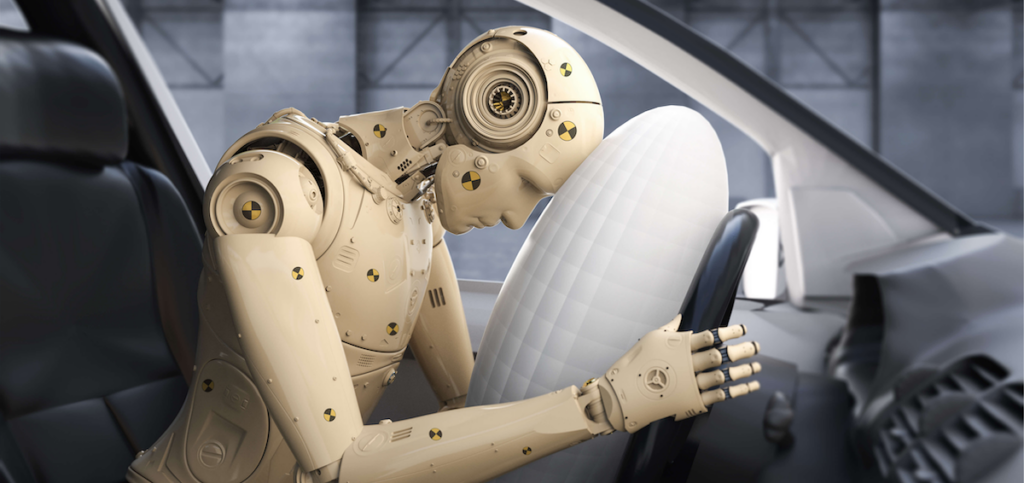

Automotive: safeguarding lives on the road

In the automotive industry, functional safety is of the utmost importance. With the increasing complexity of vehicle electronics and the rise of autonomous driving, the potential for system failures to cause catastrophic accidents is ever-present. Spyrosoft’s functional safety engineers work closely with automakers and suppliers to ensure compliance with ISO 26262, verifying that safety-critical systems are designed, tested, and validated to the highest standards. By integrating functional safety into the entire product development lifecycle, we help our clients deliver vehicles that prioritize the protection of drivers, passengers, and other road users.

Medical: ensuring patient safety and device reliability

For medical device manufacturers, functional safety is a crucial consideration to protect patient health and well-being. Spyrosoft’s experts leverage their expertise in IEC 62304 to guide clients through the development of safe, reliable, and compliant medical software and hardware. From risk assessment to verification and validation, we work to identify and mitigate potential safety hazards, ensuring that medical devices function as intended and minimise the risk of harm to patients.

Industry 4.0: safeguarding smart factories

The rise of Industry 4.0 and the increasing adoption of automation have introduced new functional safety challenges. As industrial systems become more interconnected and autonomous, the potential for system failures to cause injury or damage has grown exponentially. Spyrosoft’s functional safety specialists draw upon their expertise in standards like IEC 61508 to help clients in the industrial sector develop safe, reliable, and compliant automation solutions.

Defence & Aerospace: keeping production safe and secure

The Defence & Aerospace sector faces critical cybersecurity challenges in its digitized manufacturing processes. To protect sensitive information and maintain operational integrity, the industry adheres to stringent standards including IEC 62443, AQAP 2110, AS/EN 9100 + 9115, ISO 27001, and Cyber Essentials Plus. These frameworks ensure comprehensive security measures, enabling companies to develop resilient, compliant solutions against advanced threats in this high-stakes environment. A functional safety focus is essential in military, aerospace, and defense systems to analyze and verify safety-critical functions and ensure compliance with standards like IEC 61508.

Robotics: ensuring safe human-robot collaboration

As robots become more prevalent in industrial, medical, and service applications, the need for robust functional safety practices is paramount. With robots increasingly required to operate in close proximity to human workers, the risk of malfunctions causing harm has increased significantly. Spyrosoft’s experts leverage their deep understanding of standards like ISO 13849 to guide clients through the development of safe, collaborative robotic systems.

how we can help you

Functional safety assessment and workflow design

Functional safety analysis and process design encompass several key areas of focus, including safety concepts, safety requirements, failure mode and effects analysis (FMEA), and assumptions of use (AoU). These elements are crucial for ensuring the safety and reliability of systems and products.

Additionally, functional safety services play a vital role in managing and optimizing safety systems from design to performance assessments. This comprehensive approach to functional safety analysis and process design ensures that all aspects of safety are considered and integrated throughout the development process, from concept to implementation.

Safety concepts

- Verify that technical concepts align with Functional Safety Requirements and ensure that each safety function meets the necessary performance metrics, using system-level input

- Collaborate with the team to develop functional fafety concepts within the project scope

- Identify and select the most effective approaches to support the safety concept

- Implement strategies such as Fault Handling and L2 Operating State Monitoring

Safety requirements and Functional Safety standards

- Conduct Requirements Engineering for ASIL (Automotive Safety Integrity Level) relevant content, ensuring that safety integrity levels (SILs) are considered to achieve the necessary risk reduction in compliance with standards such as IEC 61508, EN 50128, and ISO 26262.

- Review and propose safety-related requirements

- Ensure thorough reviews of Functional Safety Requirements are performed

Multi-tiered analysis of programmable electronic control systems

Analysing safety critical functions to ensure proper verification and risk mitigation in system, hardware and software interactions.

-

- FTA – Fault Tree Analysis

- FMEA – Failure Mode and Effect Analysis

- FMEDA – Failure Mode, Effect and Diagnostic Analysis

- DFA – Dependent Failure Analysis

- ETA – Event Tree Analysis

Functional safety assumptions of use

- Manage and review Assumptions of Use (AoU) in the context of a safety-related system

- Make informed decisions on incorporating AoU into safety manuals or safety requirements

- Establish links between AoU and requirements for other development layers

why work with us

Our principles in delivering functional safety

We understand the rigorous safety and quality standards these fields demand, and we know how to help organisations navigate complex certification processes and regulatory frameworks. Adhering to functional safety standards like IEC 61508 and ISO 26262 is crucial for compliance and ensuring product reliability. Functional safety systems play a vital role in preventing dangerous incidents and enhancing operational efficiency. Additionally, programmable electronic control systems are essential for ensuring the safe operation of equipment across different applications.

Transform your functional safety challenges into opportunities with Functional Safety Certification Programs

Insights from our experts

contact