IoT hub: what it is and how to incorporate it in your IoT system

The Internet of Things (IoT) is one of the backbones of the fourth wave of the Industrial Revolution (also known as Industry 4.0). With the price of IoT sensors dropping to a historic low (by 200% since 2004) and off-the-shelf solutions available, it’s now easier than ever to increase the digitalisation rate in an Industry 4.0 organisation of any size.

In 2020, Deloitte surveyed CXOs working in Industry 4.0 to understand their challenges and the type of projects they focus on. 72% of them agree that IoT will be the technology with the biggest impact on their organisation over the next few years, even though all of the ‘big four’ technologies in the sector (Internet of Things, Artificial Intelligence, Cloud infrastructure, and Big Data) are gradually becoming more intertwined.

As Ram Jambunathan, SVP and Managing Director at SAP, states in the report:

There is a strong correlation and dependencies between several Industry 4.0 technologies. IoT sensors will generate a ton of data that will be relevant for machine learning-based automation. Many of these technologies will be delivered and consumed in the cloud even as we see the emergence of edge computing. Next-gen robotics will see the convergence of IoT, machine learning, and cloud computing as robots start getting better through cloud-based machine learning from data from IoT sensors in the robots.

With the dominant role of IoT and data collection in the sector, one element of the IoT system will be crucial for further development: the IoT hub. In today’s article, I’ll explain in detail what it is, what off-the-shelf IoT solutions are currently available, and the process for introducing IoT hubs on the organisational level. The blog post was written in collaboration with Spyrosoft’s Lead Embedded Architect, Krzysztof Maciejewski.

But before we get started, let’s once again define what the Internet of Things means for industrial development.

Looking for an experienced team for your Industry 4.0 project? Check our offer

Learn moreIoT solutions and the Industry 4.0

The Internet of Things allows devices to connect to the internet. These devices need to be autonomous, and they can use this connectivity to provide different services to the end users, e.g., remote vehicle monitoring, including the vehicle location and route. Another use case is an intelligent building with multiple connected devices, or industrial machines managed using steering algorithms. IoT can also be used for data collection, and that’s its most common use.

The term’ Internet of Things’ is often used for a subset of connected small household appliances, but it can also be used in the Industry 4.0 context, where instead of these small devices, we have industrial machines and a plant. Regardless of how it’s used, the term refers to a case where the devices can gain additional functionalities thanks to their connectivity to each other and to the internet.

By placing IoT sensors on the devices, you can collect the data, i.e. about the temperature, air quality, etc., and it is then transferred to the cloud where it’s made available to different applications that can use the data and process it. Please note that the communication between the devices and the applications can be bi-directional: devices can be managed via external applications, i.e. for access management purposes. IoT devices exchange data with each other and cloud services, facilitating various messaging patterns and supporting scalability to millions of devices and events per second.

Here, you can find out more about IoT architecture.

What is an IoT hub?

The main goal of an IoT hub is to store the collected data so it can later be used in data processing and management. This solution can be developed independently, but ready-made products are available on the market – I’ve included a full list below.

IoT hub is a Platform-as-a-Service (PaaS) managed service that can be used as a central message hub that allows devices to be connected to the internet. On one side, there are the devices that send their data from the sensors to the hub and/or receive the information from the hub. On the other hand, some applications may or may not be cloud-based and can manage the devices and process the data, i.e., visualise it.

IoT hubs support various messaging patterns, including device-to-cloud messages, ensuring secure and reliable communication between IoT devices and cloud services.

In short, the IoT hub serves as a mediator between these devices and applications, which are used to manage them and collect data.

What are the benefits of using IoT hubs?

Security

Most of the solutions available on the market have at least a few ways to manage who and what devices can access them. These include the ability to build a device registry into the hub, distribute shared access signatures using access keys and security tokens, and integrate APIs to increase the security of these solutions.

Complete control over the process

Once you’ve completed the IoT hub implementation process I’ll mention below; you can precisely control what devices are interconnected, what data they collect and share (be it with each other or external applications) and where the data are stored and processed.

Scalability

Regardless of how large or small your IoT networks are right now, you can easily add new devices or even a set of devices or limit their number by using an IoT hub. Again, with most of the ready-to-use IoT hubs available on the market, you can do it in a matter of minutes.

Learn more about IoT in Industry 4.0 from our guide

Download the ebookIoT hubs available on the market for IoT devices

- Amazon Web Services (AWS) IoT Core: AWS IoT Core offers secure, reliable, and scalable connectivity between IoT devices and the cloud, with real-time data processing and extensive integration capabilities.

- Microsoft Azure IoT Hub: Azure IoT Hub provides robust communication between IoT applications and devices, supporting device management, monitoring, and integration with other Azure services for advanced data analytics and storage.

- IBM Watson IoT Platform: IBM Watson IoT Platform focuses on collecting, analysing, and visualising IoT data using machine learning models, ensuring security at both device and data levels.

- Cisco IoT Cloud Connect: Cisco provides a comprehensive solution for managing mobile IoT devices, focusing on network optimisation, security, and extensive device management capabilities.

- Oracle IoT Cloud: Oracle IoT Cloud offers secure, real-time analysis of IoT data, built-in integrations with other Oracle services, and unique digital identities for each device.

- Salesforce IoT Cloud: Salesforce integrates IoT data with its CRM system, enabling real-time insights and improved customer experiences, with capabilities to process billions of events daily.

- Siemens MindSphere: Siemens MindSphere is tailored for industrial IoT, providing tools for collecting and analysing data from industrial machines, supporting digital twins, and integrating with various IT systems.

- ThingWorx (PTC): ThingWorx offers rapid IoT application development, device management, and real-time monitoring, which are suitable for both industrial and commercial IoT projects.

- Particle: Particle specialises in cellular IoT deployments, offering robust device management through its Device Cloud and integration with major cloud platforms like AWS and Azure.

- Ayla Networks: Ayla Networks provides an agile IoT platform focusing on secure connectivity, data analytics, and feature-rich customer experiences, suitable for various IoT applications.

What is the process of building an IoT system?

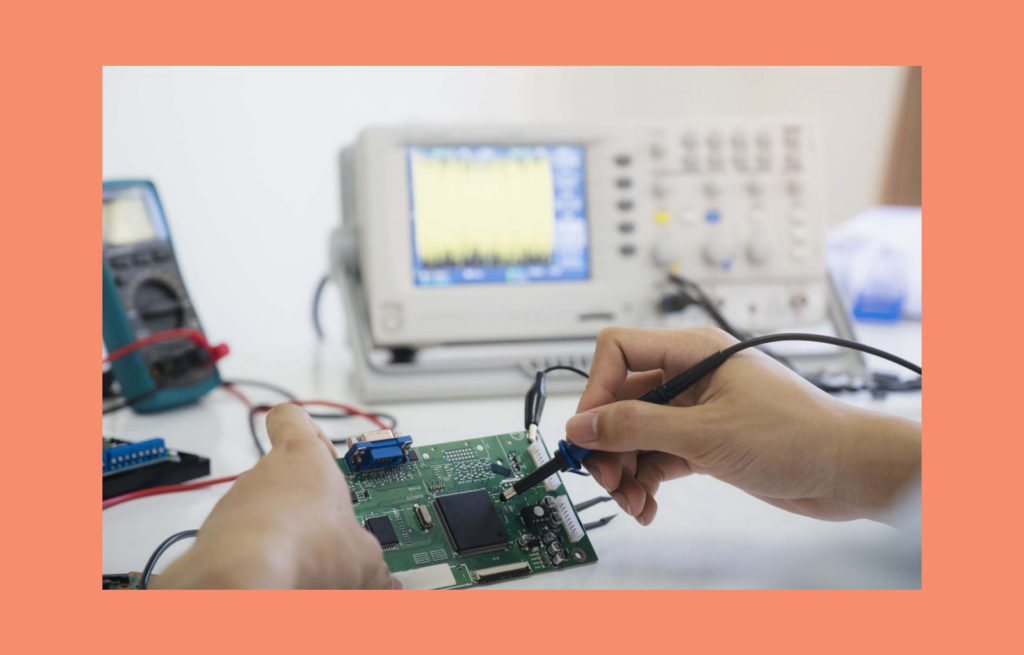

The first thing to do is connect all devices to the internet. If the device already has a connectivity setup installed, all you need to do is to bring it online. Device connections are crucial for enabling communication between the IoT application and its attached devices. When you plan for data collection, you need to think about what data you may need to collect and then decide where to place the sensors, what type they should be, and what software would be best for data aggregation and receiving requests. This stage of the process requires not only thinking about the electronics (sensors) part but also about the mechanics behind the data collection and device steering process. Device creation is an important step in setting up your IoT ecosystem, ensuring each device is configured correctly and connected. The sensors can also be used to expand the functionalities of a device.

The next step is to build a cloud-based application that can store the data and be used to steer and communicate with the devices.

Completing this process can be the foundational level for introducing Predictive Maintenance for connected devices via the IoT hub. The latter can play a crucial role in collecting functional data about the status of the devices and any failures that occur in their performance. It can help diagnose these failures and send the information necessary to fix those to a ticketing system or directly contact people responsible for the maintenance of the devices. It can be used to change the settings for any of the devices and update/replace their software – all completed remotely. Additionally, using monitoring capabilities in cloud IoT hubs allows you to track device creation, connections, and failures, ensuring the health and performance of your IoT ecosystem.

Here, you can read about IoT hub use cases.

What are the best practices for IoT device management?

Once the IoT hub is implemented and ready to use, the next thing to do is to start managing your fleet of IoT devices. Here’s a list of actions to take if you’re doing so from our Lead Embedded Architect, Krzysztof Maciejewski:

- Use automation as much as possible.

- Automatically discover any Internet access problems from the devices and improve the connection if needed.

- Automatically monitor the device’s health and replace/fix them in case of any failures.

- Use device firmware updates over the air if needed.

- Easily scale up your solution by adding new devices and functionalities, introducing AI usage, and/or extending cloud computing.

Over to you

At Spyrosoft, we’ve worked with multiple customers from the Industry 4.0 sector and have hands-on experience in building and scaling industrial solutions. If you’d like to know about our offering or you need a team of experts to support your IoT project, check more information on our Industry 4.0 subpage and book a no-obligation call.

About the author

RECOMMENDED ARTICLES