Top 5 hidden cold chain cost leaks (and how predictive maintenance solves them)

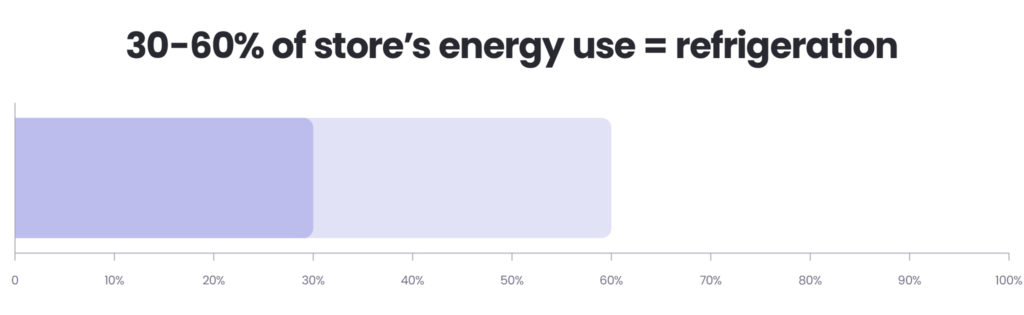

Every grocery store runs on the cold chain. Behind the shelves of milk, produce, and frozen meals, refrigeration is the lifeline that keeps everything fresh. Yet it’s also one of the biggest drains: cooling alone can devour as much as 30-60% of store’s energy use.

Cold chain risks

The trouble is that your cold chain, counterintuitively, can burn through money really fast. A small leak, or a compressor running longer than it should, can quietly push the expenses up. First in energy bills, then in food waste, and finally in equipment breakdown.

That’s the real risk of the cold chain: the most expensive problems are often the ones you don’t see coming.

In reality, many large retail chains still operate in silos. Each store runs its own systems, with no shared data, no central control, and little to no predictive maintenance in place. Equipment servicing is delayed, failures are often caused by human error, and by the time issues are spotted – the damage is done.

For some European retailers, these inefficiencies already translate to losses of $10-30 million annually from spoiled food alone. It’s a problem too big to ignore – and the opportunity for improvement has never been greater.

Predictive maintenance, powered by AI and IoT, helps retailers spot the hidden losses and take control. Here’s how it tackles the five biggest cost traps in cold chain operations.

5 hidden cost leaks in cold chain operations

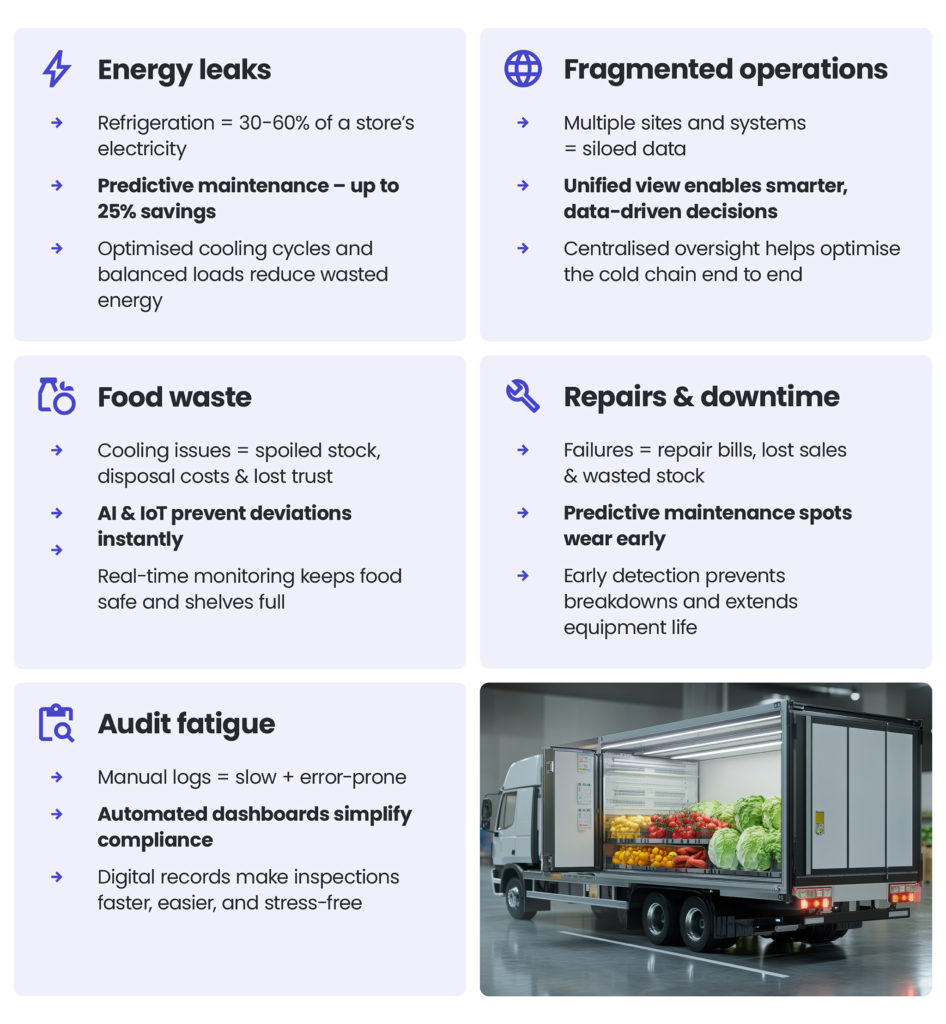

1. Energy leaks

As we already mentioned, refrigeration is the largest energy expense, often consuming more than half of a store’s electricity. A mistimed defrost cycle or a slightly worn component can quickly add thousands to the monthly bill.

The good news? Even small adjustments deliver savings. UK trials show that raising freezer temperatures from -18 °C to -15 °C reduces energy use and CO₂ emissions. Multiply that across every aisle and store, and the impact becomes massive.

Predictive maintenance goes a step further.

While predefined settings can help keep energy use in check, predictive maintenance ensures those conditions are actually met. It continuously monitors equipment performance in real time, instantly alerting you to any anomalies in temperature, pressure, or compressor loads.

On top of that, it can automatically recommend/trigger operational adjustments, such as optimising defrost cycles or balancing loads across units and sites (even when stores currently operate as separate systems).

The result: up to 25% lower refrigeration costs.

2. Fragmented operations

Running hundreds of stores and distribution centers is a challenge in itself. Add refrigeration systems from different vendors and siloed data, and optimisation becomes nearly impossible.

This fragmentation is still the reality for many chains today. Most stores work independently, using their own hardware, sensors, and logic controllers (none of which communicate with each other). There’s no unified view of energy usage, equipment health, or failure patterns. That lack of visibility makes it hard to plan resources abd scale improvements across the network.

A predictive maintenance approach brings everything together. Data from every site and system flows into one control center. Leaders get an eagle-view of their operations (energy use, equipment health, compliance), all on a single dashboard. This holistic visibility helps with staffing, enables remote troubleshooting, and reduces firefighting.

Ultimately, such a system can evolve into a broader control platform managing not only refrigeration but also lighting, HVAC, and power distribution, driving even greater efficiency gains.

Cut hidden cold chain costs with IoT monitoring

Learn more3. Food waste

Spoiled food costs you twice. First when you buy it, and again when you pay to throw it away – plus the lost revenue and customer trust.

Small issues like uneven temperatures, compressor malfunctions, or even a door left open too long can cause spoilage. Without connected systems to detect and act on those anomalies, these problems can go unnoticed until it’s too late.

Retailers without connected cold chain systems can lose tens of millions of dollars every year. Some chains lose between $9-13 million annually due to refrigeration failures that could have been prevented.

Here’s where IoT sensors step in, feeding real-time data into AI models and instantly capturing the smallest deviations. This keeps your food safe and reputation intact.

4. Repairs and downtime

Few things are more disruptive than a refrigeration unit breaking down during peak hours. Traditional maintenance tends to be reactive, waiting until something breaks before acting. The cost of that approach is high: lost sales during downtime and entire cold stores of spoiled food that have to be thrown away.

With live performance tracking, predictive maintenance platforms spot problems early so teams can fix them before anything breaks. This means lower repair costs, less downtime, and longer-lasting equipment.

Over time, the system learns and automates most of the process. It can automate service scheduling and parts replacement, removing the human factor that currently causes many failures.

5. Audit fatigue

Compliance with food safety regulations is non-negotiable, although it’s often time-consuming and stressful. Teams spend hours collecting temperature logs, alarm histories, and reports. Audits turn into paperwork marathons instead of quick check-ins.

Predictive platforms automate the process. Data from every refrigeration unit is captured continuously, stored securely, and ready to export as an auto-generated audit pack. Manual prep that once took days is done in minutes.

At the same time, as regulations like NIS2 and standards such as IEC 62443 evolve, the stakes keep rising. Platforms built with security-by-design principles give retailers confidence that their operations are resilient on every front.

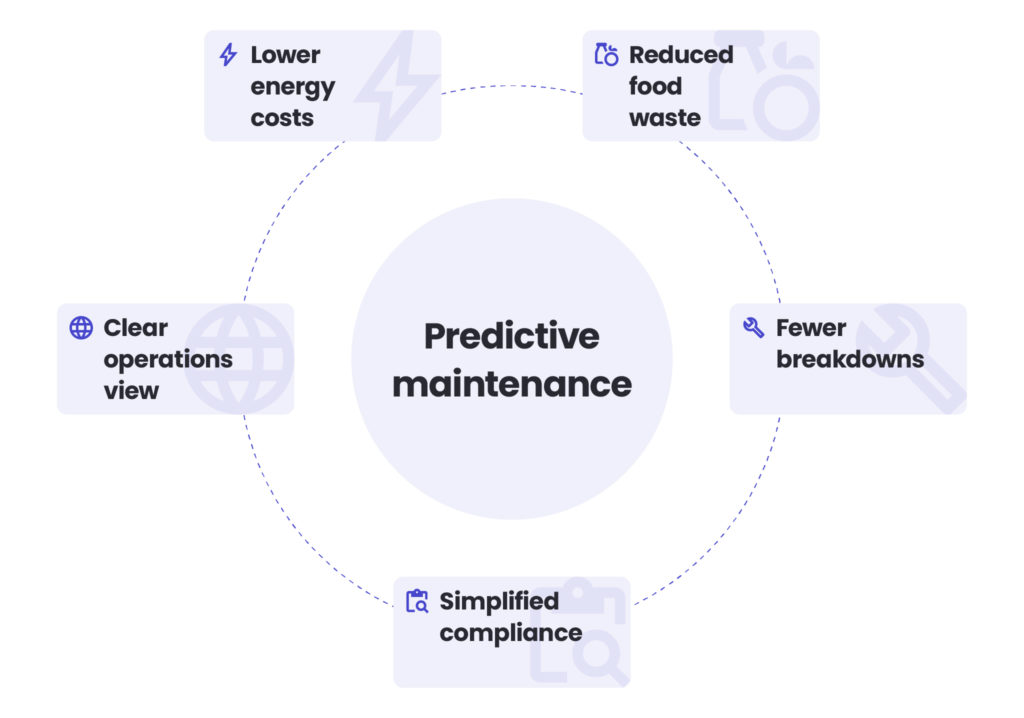

Why predictive maintenance pays off

Cold chain inefficiencies may be hidden, but their impact is very real. It’s felt everywhere: in higher bills, wasted stock, stressed teams, and shrinking margins. Predictive maintenance brings those blind spots into the light and turns refrigeration into a controlled, optimised system.

Let’s see the benefits:

- Up to 25% lower energy costs

- One clear view across operations

- Reduced food waste and spoilage

- Fewer breakdowns and emergency calls

- Automated compliance and faster audits

And what can we offer you at Spyrosoft? We combine engineering know-how, AI expertise, and cybersecurity strength to modernise grocery cold chains. Unlike OEMs tied to specific products or consultants who stay high-level, we’re vendor-agnostic and hands-on, making every system work seamlessly to deliver measurable ROI.

The cold chain market is still in its early stage of digital maturity, meaning that the biggest opportunities lie ahead.

How IoT monitoring is revolutionising grocery cold chains (and cutting costs)

Go to the articleReady to cut hidden cold chain costs?

Hidden cost killers don’t have to drain your margins. With AI-driven predictive maintenance, you can cut energy costs, protect food quality, and simplify compliance – in every store and distribution center.

Contact us to see how Spyrosoft can help optimise your cold chain.

About the author

contact us

Let’s optimise your cold chain operations

Recommended articles

![[industry 4.0] how IoT monitoring is revolutionising grocery cold chains (and cutting costs)](https://spyro-soft.com/wp-content/uploads/2025/10/adobestock_845811382-2-300x150.jpeg)