How IoT monitoring is revolutionising grocery cold chains (and cutting costs)

Walk into any grocery store, and you’ll notice the surface details: rows of perfectly chilled produce, dairy, and frozen goods. What you don’t see is the complex network of refrigeration systems that got these products to the shelves and is now working constantly to keep everything at the right temperature. This cold chain is the backbone of modern grocery retail, but it’s also one of its biggest cost centres, and one of the least digitally connected.

Cold chain management needs an upgrade

For many retailers, managing the cold chain hasn’t changed much in years. Temperature checks are often done manually, systems run as isolated “islands”, and fixes are reactive. In many cases, real-time visibility is the missing link.

In fact, across major retail chains, food spoilage alone can cost millions every year. For example, in Poland’s leading grocery brands, losses are estimated at around $8-12 million annually.

IoT monitoring gives you a new approach. By connecting refrigeration equipment, sensors, and data into one real-time view, you can gain full visibility across every store and warehouse. It’s simple, scalable, and delivers big savings.

In this article, we explore why IoT monitoring is becoming increasingly essential for grocery cold chains and how it can transform your operations.

IoT monitoring reduces energy waste

Refrigeration can account for up to 60% of a grocery store’s electricity use. That’s a huge chunk of your operating costs. Even small inefficiencies can quickly multiply across dozens or even hundreds of locations.

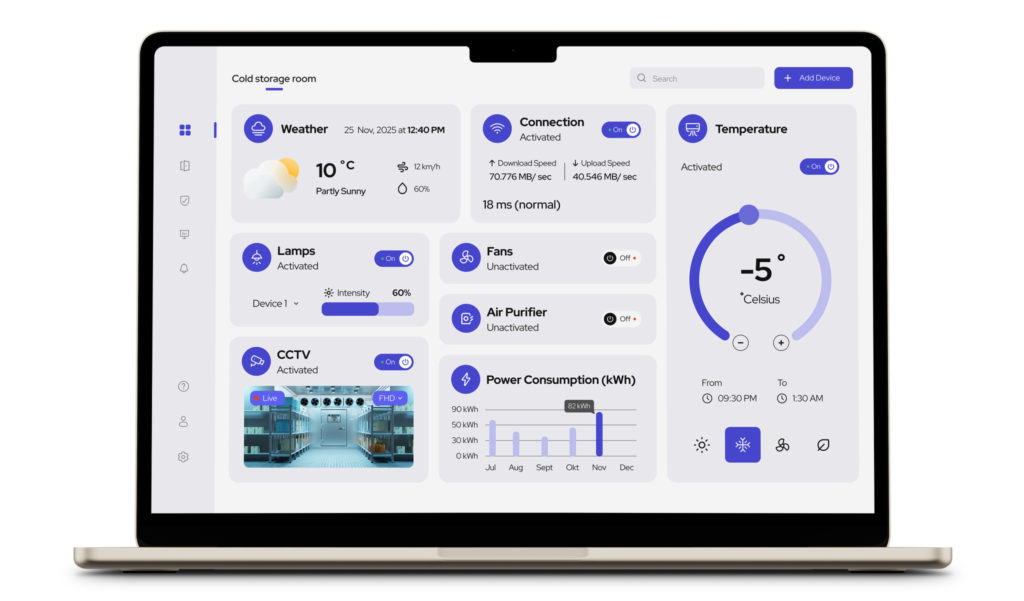

With IoT monitoring, you see it all – it gives you a clear, real-time picture of where energy is being used and where it might be wasted. Sensors track temperature, compressor performance, and defrost cycles, while analytics highlight opportunities to optimise usage. Everything appears in a live dashboard.

You see the benefits right away: better load balancing, more accurate cycle adjustments, and instant alerts when something is off (e.g. when the system detects a leak or an underperforming unit).

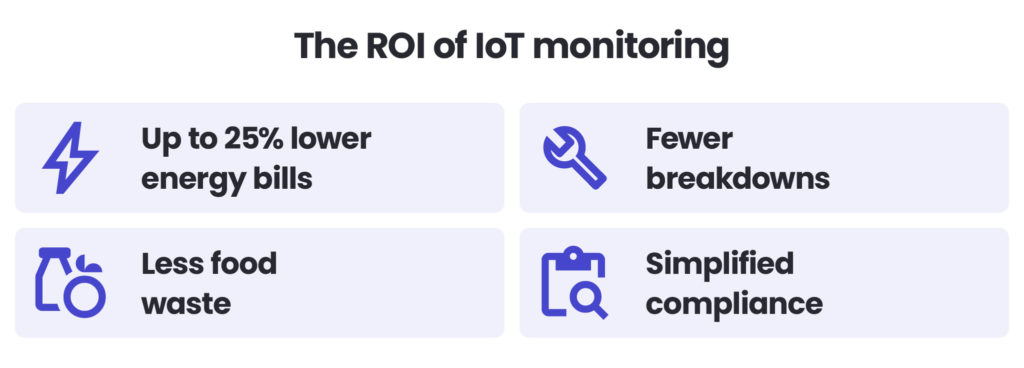

Across an entire chain, these improvements can deliver substantial savings: cutting energy bills by up to 25%, while also reducing your carbon footprint.

IoT monitoring keeps food fresh (and customers loyal)

Even a small change in temperature can ruin a whole batch of produce, turning your investments into waste. Spoiled food costs you twice – first when you buy it, then again when you have to throw it out.

IoT monitoring can protect your inventory. Sensors track conditions in every fridge and freezer in real time, while analytics instantly flag even the tiniest cooling deviations. That gives your staff the chance to act before spoilage ever happens.

The impact? Less waste, lower costs, and customers who know they can rely on your store for fresh, high-quality products every time.

Cut hidden cold chain costs with IoT monitoring

Learn moreIoT monitoring prevents costly downtime

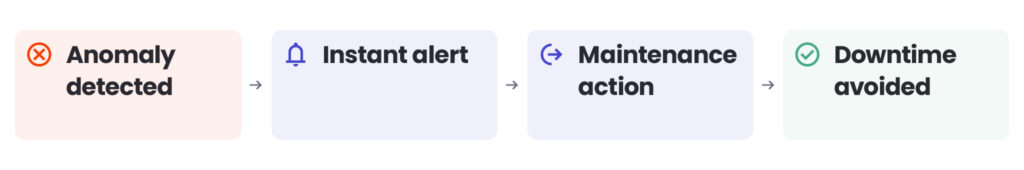

A freezer stops working in the middle of the night. Emergency repairs are expensive, sales are lost, and entire cold stores have to be discarded. Chaos, in other words.

It’s a common scenario, as most retailers still rely on reactive fixes and long service intervals. Many failures come down to human error or a missed early warning sign.

Now imagine the same store with IoT monitoring. By tracking every unit continuously, IoT systems detect early warning signs before they become problems. Maintenance teams get instant alerts that let them act before downtime hits.

Proactive maintenance means fewer breakdowns, lower repair bills, and a cold chain that keeps running smoothly.

IoT monitoring simplifies compliance and reporting

magine walking into a store and knowing instantly that every fridge, freezer, and cold display is within the right temperature range – without flipping through spreadsheets or paper logs. No surprises and no stress.

That’s the reality that IoT monitoring creates. Data flows automatically from sensors to a secure dashboard, building a complete, audit-ready record. Trends are easy to spot, reports can be generated in seconds, and your team spends less time chasing logs and more time running operations.

Compliance stops being a chore. It becomes transparent, reliable, and worry-free. It lets you focus on what really matters: keeping products fresh and costs under control.

Explore top 5 cold chain cost leaks (and learn how to solve them)

Go to the articleConclusion: One connected view, clear ROI

Hundreds of stores, multiple vendors, and dozens of systems… It all results in siloed data that slows your decision-making.

With IoT monitoring, everything is unified into one dashboard. As a decision-maker, you get a clear overview of the entire cold chain. You can see the full picture, spot issues faster, and make smarter operational choices.

Here’s the impact that you can benefit from: lower energy bills, less waste, fewer breakdowns, and streamlined compliance. From energy use to food waste, the ROI is clear and measurable.

And this is just the beginning: the same IoT infrastructure can easily expand to cover lighting, HVAC, and power distribution, creating a complete facility management ecosystem.

Curious where exactly IoT can uncover hidden costs in your cold chain? Contact Spyrosoft to find out.

About the author

contact us

Let’s optimise your cold chain operations

Recommended articles