Automation process digitalisation – comprehensive solutions for Industry 4.0

The effective combination of Industry 4.0 and software engineering solutions enables organisations to achieve global sustainability goals, increase production efficiency and reduce costs. Responding to the market’s needs at Spyrosoft, we provide software development services to our customers, improving quality management and supply chain management as well as securing organisations against increasingly intense cyber-attacks. The challenges facing manufacturing, or the industry more broadly, are constantly growing, and automation process digitalisation is the answer.

Which companies is the automation process digitalisation service for?

We specifically target our services to two types of companies.

- Those in the manufacturing industries

- Automation equipment suppliers

Whether your manufacturing enterprise is in electronics, automotive, or FMCG, or it owns production lines, executes orders for a factory, or supplies factories with components needed to build production line automation, process digitalisation services will allow you to maximise your process efficiency.

We take full responsibility

We do not call ourselves “integrators.” We don’t use the team extension or body leasing model. We take responsibility for the whole process and help you optimise it as efficiently as possible. Our focus is on transparency and the high quality of our services, as evidenced by our standards.

IEC 62443 – THE STANDARD FOR THE CYBER SECURITY OF INDUSTRIAL NETWORKS

International standard IEC 62443 indicates the most critical security risk prevention requirements for component manufacturers, system integrators, and users. Adherence to this standard ensures the safe operation of industrial automation systems at every stage, from design to implementation to management.

IEC 61508 – FUNCTIONAL SAFETY

The second primary international standard is the equivalent of ISO 26262, which is well-known to companies in the automotive industry. This standard aims to minimise unacceptable risks and hazards by effectively managing the entire product life cycle according to a risk-based approach: from the conceptual work stage, design and development, to production and operation.

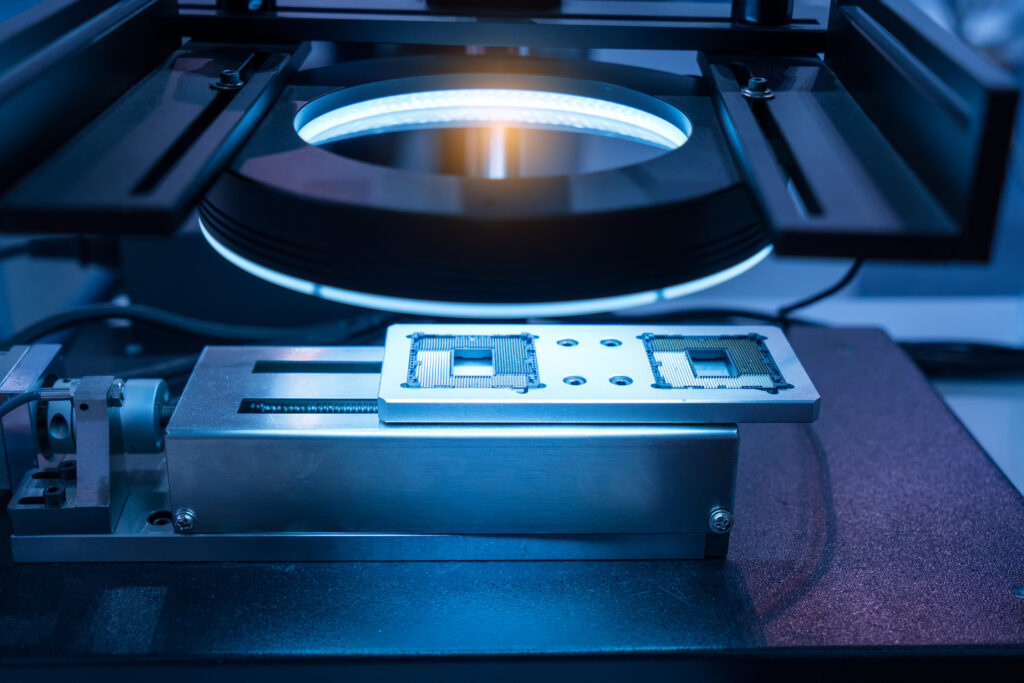

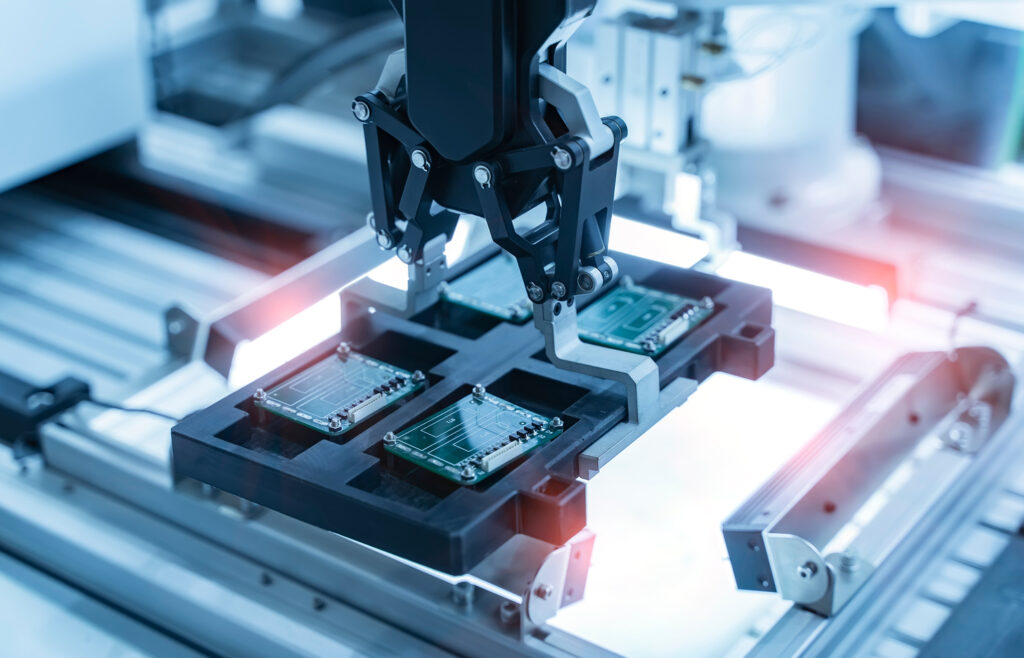

We partner with our clients in manufacturing excellence by implementing technologies that drive innovative solutions.

We support our customers in 5 critical areas

Manufacturing in the era of Industry 4.0 faces many enormous challenges. At Spyrosoft, as a provider of automation process digitalisation services, we want to help businesses in those areas where we excel and where we can offer practical solutions and tools.

PRODUCTION EFFICIENCY

Managing production efficiency is the biggest challenge the manufacturing industry has faced for years. We help factories optimise processes to run as intended through digital process automation services.

SUPPLY CHAIN MANAGEMENT

You can’t produce anything if the supply chain is not functioning correctly. The absence of even one small component out of the hundreds or thousands necessary to have a product, makes production impossible. You must ensure that essential details are delivered on time, which is only made possible by a well-functioning supply chain.

The digitalisation of supply chain management includes among many things: advanced forecasting based on predictive analytics of market trends, weather, customer demand, etc, automation of tasks or integrated planning through interconnected supply chain management software. Digitalisation can also significantly improve warehouse management capabilities through real-time tracking.

SHORTAGE OF RESOURCES

In recent years, due to several unexpected global events, the manufacturing industry has been facing a growing shortage of resources. The problem with the availability of products was particularly evident in the field of electronics. As a civilisation, we are slowly coming to a point where some resources have almost been depleted. Therefore, the manufacturing industry needs to optimise its processes and manage them better to cope with shortages or difficult availability of vital components or equipment.

SUSTAINABILITY

The sustainable manufacturing approach ensures that the business operates responsibly and does not abuse resources. That is a growing trend nowadays, so companies should include it in their strategy alongside actions to guarantee their growth and global competitiveness.

CYBER THREATS

In the past, you had to be on the factory floor to physically access equipment. Today, most data and processes are connected to the internet in the cloud, which means they are becoming highly accessible to cyber hackers. Digital threats are increasing in scale every year, and more and more cyber-attacks are emerging that target industrial players directly. While in the service industry, cyber-attacks can paralyse a company’s operations for some time, in the case of manufacturing, a malfunction in production can endanger those in the vicinity of machinery and equipment. That’s why it’s essential to secure processes, identify potential vulnerabilities and respond immediately and effectively.

We turn company challenges into our key specialities

Thanks to our international expertise and close cooperation with our customers, we understand the manufacturing industry’s needs and the challenges companies face. That enables us to create dedicated solutions to their challenges and provide the best digital automation tools. We can help you with:

CONNECTIVITY AND M2M COMMUNICATION

The digital revolution has brought all kinds of devices into the manufacturing industry for good, and there are more and more. These devices connect by both wired and wireless means and need to communicate with each other effectively. However, this communication can sometimes be challenging due to the different standards used by equipment suppliers and various types of interfaces or plugs. Moreover, various information can flow through these different connections, which are recorded using other communication protocols.

At Spyrosoft, we help customers meet this challenge. We know protocols and can put all the pieces of the complicated puzzle together into a single, coherent protocol. Then, we take it upon ourselves to build all the necessary back end, providing the tools required to enable our customers to take control of all connections, whether wired or wireless.

FUNCTIONAL SAFETY AND CYBERSECURITY IN INDUSTRY 4.0

Based on the IEC 62443 and IEC 61508 standards, our services effectively protect factory owners against human resources and financial losses. Of course, not every failure is a direct threat to human life or health, but every threat and downtime to the process generates financial losses, and we, as the automation process digitalisation service providers, know how to prevent them effectively.

At Spyrosoft, we provide similar protection to factory owners against the consequences of potential cyber-attacks aimed directly at devices or communication between them. We provide solutions whose task is to prevent external entities from disrupting (physically and remotely) the operation of the production line. We ensure that the business does not cause losses in the form of damage and danger to people. We make every effort to ensure that the factory is stable and resistant to cyber-attacks.

PRODUCTION DATA PROCESSING

At Spyrosoft, we use Machine Learning (ML) and data engineering solutions to support companies in data processing, analysis, and learning from them to grow and become competitive.

Currently, several tools on the market enable data processing and extracting relevant information from them. In the manufacturing industry, the use of data will allow you to increase production efficiency effectively. In cooperation with our clients, we focus on complementary. Therefore, we do not limit ourselves to the production itself, but we want to provide tools that will impact the entire company’s operation and all processes.

In this data, we find hidden patterns and conclude them, thanks to which we help factory owners optimise the manufacturing process and the entire business process. The mere access to and ordering data enables enterprises to make better decisions. By adding further analysis using ML or AI solutions, you can find out what to improve in the factory operation to maximise the manufacturing activity and the entire business process.

PREDICTIVE MAINTENANCE

All equipment used in the production process is consumable. So if any component fails, it can affect production and generate even multimillion-dollar losses. That’s why factories monitor the life parameters of equipment and replace them as the end of the equipment manufacturer’s declared lifespan approaches. But what if it turned out that of all the components nearing the end of their service life, only a few percent required actual replacement?

These are just hypothetical considerations, but as part of predictive maintenance at Spyrosoft, we provide factory owners with tools to monitor actual component wear, making the whole process cost-effective. Replacements are made when they are needed, not when the statistics indicate. This way, we eliminate sudden breaks and avoid over-maintenance.

Moreover, it is possible to increase asset life and set maintenance priorities thanks to predictive maintenance. Only those items that need replacing will be replaced, and we free the maintenance department’s human resources to work in those areas that need their involvement.

EDGE COMPUTING – WE MOVE DATA TO THE EDGE

Every network has layers and connection elements. Edge computing adds logic to pass the signal at the lowest possible level. Sometimes the transmission of a single signal is done through multiple devices, which creates unnecessary layers and delays the delivery of the message when we could do it at the level of a single device that does not have the necessary computing power or is not equipped with the appropriate computing function.

At Spyrosoft, we push processing as low as possible, loading the links and streamlining the message. Nowadays, all networks are loaded, and there is no need to add tens of thousands or millions of devices in all factories.

INDUSTRIAL HMI

An HMI (Human-Machine Interface) is an industrial interface between an operator and the operating machine or process. Currently, the implementation of this process is mainly done with panels, which, in industrial realities, need to be adapted accordingly. For example, in the case of touch screens, you should consider that the operator may be wearing gloves, and larger buttons will be necessary.

Moreover, the manufacturing environment does not use smartphones, which have almost unlimited possibilities for installing applications. In industry, there are numerous hardware limitations in the form of weaker processors or a limited color palette. That should be kept in mind when designing UIs and building applications. At Spyrosoft, we understand the specifics of the HMI industry and know what limitations are involved.

We make your data interactive. We don’t just visualise the data, but with HMI, we make it possible to work with this data in a feedback loop and send it further to the relevant devices. An example is the use of AR technology, which is of particular interest in maintenance departments. With the proper goggles, the repair person can have the relevant documentation displayed before him and not waste time looking for information in the manual or having to use a computer.

Automation process digitalisation service at V-model

For us, the V-model does not happen in blocks. By providing automation process digitalisation, we turn blocks into coherent and fluent processes, thanks to which we can carry out several tasks simultaneously, not one after another. At Spyrosoft, we understand the V-model, and we can do it agilely to provide automation process digitalisation service in the manufacturing industry, thanks to which you will be able to develop your business successfully.

About the author

RECOMMENDED ARTICLES