Industry 4.0

Step up your digitalisation process and become a part of the Fourth Industrial Revolution.

Challenges you may face in the nearest future

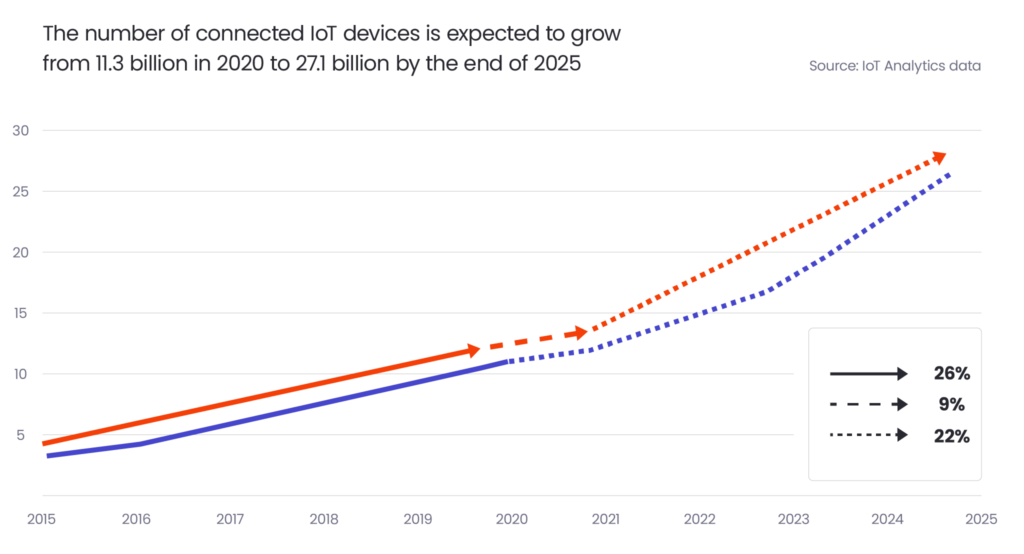

Industry 4.0 is at the forefront of the technology revolution and has the potential to disrupt and transform multiple business areas for the better, including making companies more sustainable and resilient to change. The estimated value of the industrial Internet of Things reached $123.89 billion in 2021 and is still on the rise. According to Deloitte, 72% of CXOs expect this technology to have the most profound impact on their organisations.

What can we do for you?

We provide customised solutions to our clients regardless of the industry, range of their services or stage of the digitalisation process – whether it’s Heavy Industry and Machine Connectivity or the development of Embedded Software for the producers of Heavy Industry equipment. Thanks to our extensive experience and vast knowledge of the process, we can create and adjust the solution to meet the exact needs of our clients.

Machine upgrades and connectivity

This allows you to upgrade your factory or current solutions without the need to replace them.

Connecting multiple machines

By connecting machines to one another, they can calibrate themselves automatically and exchange information.

Collecting and processing of the data

After connecting the machines, you will be able to easily collect and analyse the data for better planning and maintenance.

WHAT WE DO

From chip to Cloud and from Cloud to user

Thanks to our vast domain knowledge and a wide range of experts, we can address our clients’ needs to help them begin, continue or finalise their IoT journey. We help them to become a part of the ongoing Technological Industry Revolution. From creating customised Embedded Software to implementing Connectivity Solutions and providing our clients with ways of using the collected data – we help them achieve their goals faster and in a user-friendly manner.

01

Device

Sensor & board

We create Embedded Systems for smart devices, such as sensors and hardware platforms. They allow users to read the sensor signals live to operate the machine and collect the necessary information. This assists further business decision-making processes.

02

Network

Connectivity & security

We design and build communication solutions between all the points in the IoT ecosystem. With the use of short- and long-distance connections, we enable data transfers from the inspected machines directly to custom-built or the client proprietary internal systems.

03

Server/Cloud

Data analysis AI/ML

To analyse the received data, we configure Cloud-based platforms, powered by AI and ML algorithms. Our solutions help collect all the information in one place thanks to the use of a cloned data structure and custom-designed algorithms. They also clarify the data to help identify areas that are critical to business decisions.

04

User

Application UX

Thanks to a user-friendly application, we can help the client bridge the gap between the users and the machines. Our solutions allow for the interaction between the user and the devices or datasets. It is also where all information, machine parameters and decisions are stored.

How we can help you with your IoT journey

Digital data sourcing

The first step is the digitalisation of existing machines and the design of tracking solutions that will allow for data grabbing regarding the machine’s condition and environment.

- Device creation

- Device digitalisation

- Data collection

- Data transfer

- EDGE-computing

Gathering data

To have a broad picture of how the production works, we must gather the data and turn it into information.

- Cloud services

- Server services (e.g., backend, frontend, data exchange, data analysis, mobile app, etc.)

Using the data

Now is the time for processing the collected data using dedicated algorithms and then automating the decision-making process to reduce the user’s workload.

- Predictive maintenance

- Process automation in/by ERP, MES etc.

OUR SOLUTION

Switching your business from offline to online

If you’re facing an upgrade of asset standards to match market standards or are endeavouring to overtake your competitors in the race for the Industrial Revolution, we can help. The solution you see in the picture may be the answer to the most vital needs and challenges your business is facing. This highly customisable device can connect various assets together and, as a result, provide you with all the necessary data to make crucial business decisions faster and more precisely.

Full customisation

The device’s miniature size allows it to be contained in a small package and 3D print a specific shape to fit in any existing equipment.

Protective coat

A layer of custom protective coating can shield the device from any environmental factors like heat, humidity, dust, or radiation.

Connectivity

The two-way communication between the assets and the IoT analytics platforms opens the door to cloud-based data analysis and thus allows for the introduction of AI and Machine Learning algorithms in the gathered data.

Hot products and services

Start your Digital Transformation today. Reduce industrial waste by at least 30% and decrease downtime for your machines.

Our work

Case studies

Contact