How machine vision helps achieve the highest QA standards in manufacturing

Modern manufacturing is shaped by rising demand for high-quality products from customers and as a result of the competitive industry as well as due to strict safety and regulatory requirements. Product quality is a manufacturer’s differentiator on the market and any possible quality issues may not only slow down the production process, damage brand reputation or cause huge financial losses, but even lead to human injuries and, in some cases, death.

The long-time way for quality assurance has simply been human visual inspection. However, given the repetitiveness of the process, this method has a high risk of error and is not efficient enough. Machine vision that employs artificial intelligence and advanced optics solves these pain points and proves to be a faster and much more precise solution for quality assurance in a modern manufacturing environment.

The use of machine vision in quality assurance

The main application of machine vision is to assure high-quality product inspections to minimise product defects.

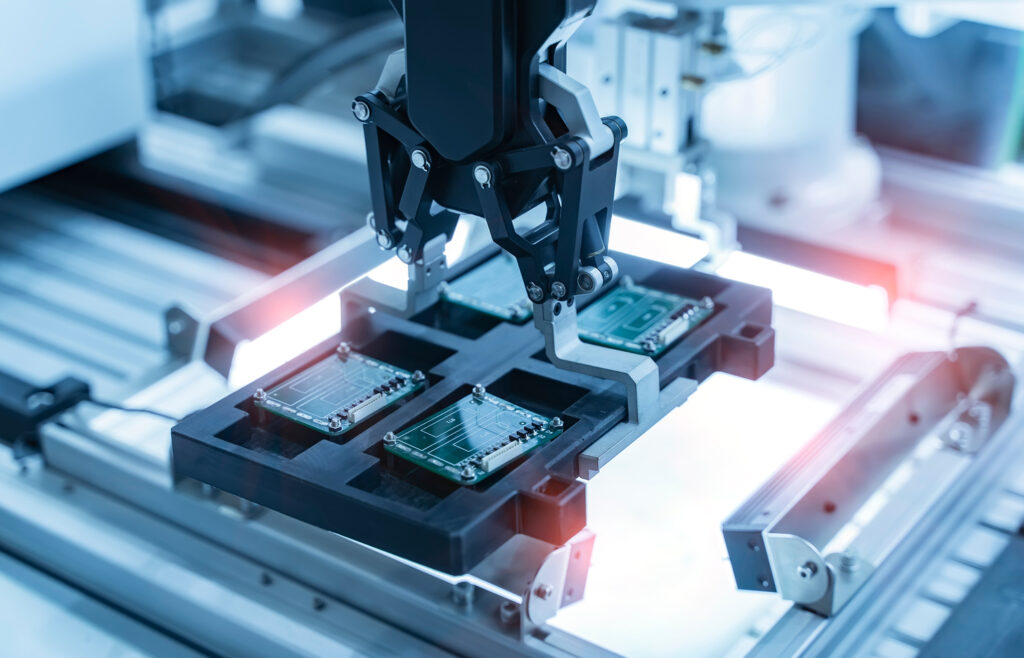

In simplified terms, the AI-based machine vision first learns to assess whether certain product details are considered acceptable or exceed the norms and must be rejected in the quality control process. There are special industrial cameras equipped with sensors and advanced optics that take photos, which are then analysed by AI-powered software and an automated decision is made in a matter of a fracture of a second.

After the machine vision system determined that a product had a defect, the findings are communicated through network to control systems and further to operations and performance improvements.

In the past, the rule-based system must have been created manually for every production case. Nowadays, deep learning method is used to train the algorithm in spotting anything that exceeds the norm based on large amounts of gathered data. The process based on deep learning mechanism is accurate, reliable and almost error-free.

Can it be used in any manufacturing case, even when the difference between acceptable and faulty products lies in very subtle details?

The smart cameras can be set up to check many variables, such as the colour, shape, size or the position of a certain element, also whether it’s missing. After capturing the picture the specially trained AI-based software detects any nuances that don’t meet the acceptability criteria. What can be inspected and controlled this way ranges from text and barcodes (thanks to Optical Character Recognition and Optical Barcode Recognition technologies), through elements almost invisible to the human eye, to the difference in colour between perfect and undone cookies.

Other benefits of machine vision in the manufacturing process

Apart from conducting the on-the-go quality assurance process in manufactories, machine vision can also bring more global and long-term benefits.

Process improvements

The data gathered from detecting defective products can be used for process improvements as in the long run it helps identify and trace large-scale problems to their source. By analysing trends in the data specific actions can be taken to better adjust the process, for example, calibrate machines, or schedule maintenance in time, to avoid potential failures and producing a large batch of defective products.

Cost savings at the end of the day

Spotting defective products early in the manufacturing process may save a huge amount of money if such a batch would have gone out to the market, not to mention reputational damage for your company. With machine vision integrated with an AI-based system, such risk is minimised as the defect risks are close to none.

Improved productivity

Quality inspection, sorting or counting is a meticulous, yet repetitive and mundane task, that machines are simply faster with and less prone to errors than humans. They can also work continuously, 24/7 providing consistent and reliable results at all times. Employees can be instead moved to more demanding roles, where the risk of burnout is much lower and they can better use their skills.

Machine vision is the tomorrow of QA in modern manufacturing processes

Machine vision combined with deep learning technology is already a highly precise and efficient quality assurance tool, which can be used for a variety of products. We can expect that with the time being as it will only become better and better at spotting the tiniest flaws, machine vision will be at the heart of every production line of modern manufacture.

About the author

RECOMMENDED READING: