Best HMI software companies in Europe in 2025

When searching for the top HMI software companies in Europe, it’s clear that the market has evolved far beyond simple control screens. Today’s HMI (Human-Machine Interface) solutions merge cutting-edge UI/UX design, embedded development expertise, and robust system integration to power everything from industrial automation panels to next-generation automotive cockpits.

In this guide, we explore 10 leading HMI software development companies shaping the industry in 2025, from innovative design houses to full-stack engineering providers. Each profile includes an in-depth look at their offerings, technologies, notable projects, and the industries they serve.

Spyrosoft

More than a software vendor, Spyrosoft is a full-stack HMI technology partner, delivering end-to-end HMI development for automotive, industrial automation, robotics, and medical devices.

Our approach blends system-level and component-level design with UI/UX engineering and embedded software development, ensuring every interface meets both functional demands and industry-specific compliance requirements.

Core HMI capabilities and technologies:

- UI/UX Design for Embedded Devices: pixel-perfect, responsive interfaces optimised for sunlight readability, low-latency interaction, and multi-modal input (touch, voice, gestures).

- Embedded software development: protocol integration including CAN, ModBUS, NMEA 2000, LIN, Bluetooth, and vendor-specific standards such as Raymarine SeaTalk, Furuno NavNet, SimNet, OneNet.

- Cross-platform HMI solutions: development in Qt, Android Automotive, QML, HTML5, and Unity-based visualisations.

- System integration and testing: hardware-software integration, simulation-based verification, and HMI performance optimisation.

We’ve delivered advanced HMIs for:

- Thermomix® TM7

- Connected vehicles: automotive clusters, infotainment, and driver assistance displays.

- Smart marine control panels: multi-screen helm stations and navigation dashboards.

- Industrial robotics dashboards: real-time machine control and monitoring UIs.

- Healthcare touchscreens: medical device HMIs meeting strict usability and safety requirements.

Projects often serve OEMs and Tier-1 suppliers in Europe and North America, operating under rigorous safety and quality frameworks such as ISO 26262, IEC 62304, and IEC 61508. This combination of domain-specific expertise, broad technology stack, and compliance readiness positions us as a go-to partner for organisations seeking high-performance, standards-compliant HMIs.

We adapt our collaboration model to fit your project, not the other way around. Do you need a fully managed, end-to-end solution? Our team can take it from concept to deployment. Prefer a joint approach with your in-house developers, full access to source code, and clear documentation? We’ll integrate seamlessly into your workflow.

And our commitment doesn’t end at go-live. With dependable post-deployment support, we make sure your solution keeps delivering, giving you the technical assurance and long-term peace of mind to focus on what’s next.

If you want to discuss your HMI solutions ideas, get in touch and we’ll see what we can do.

Qt Group

The Qt Company, headquartered in Helsinki, Finland, is a global leader among HMI software companies, known for delivering one of the most versatile and high-performance frameworks for creating modern, graphics-rich interfaces. Its flagship Qt framework is a cross-platform powerhouse, combining robust C++ libraries with the intuitive QML language, enabling teams to design responsive and visually compelling HMIs that run seamlessly on Linux, QNX, Windows, Android, iOS, and more.

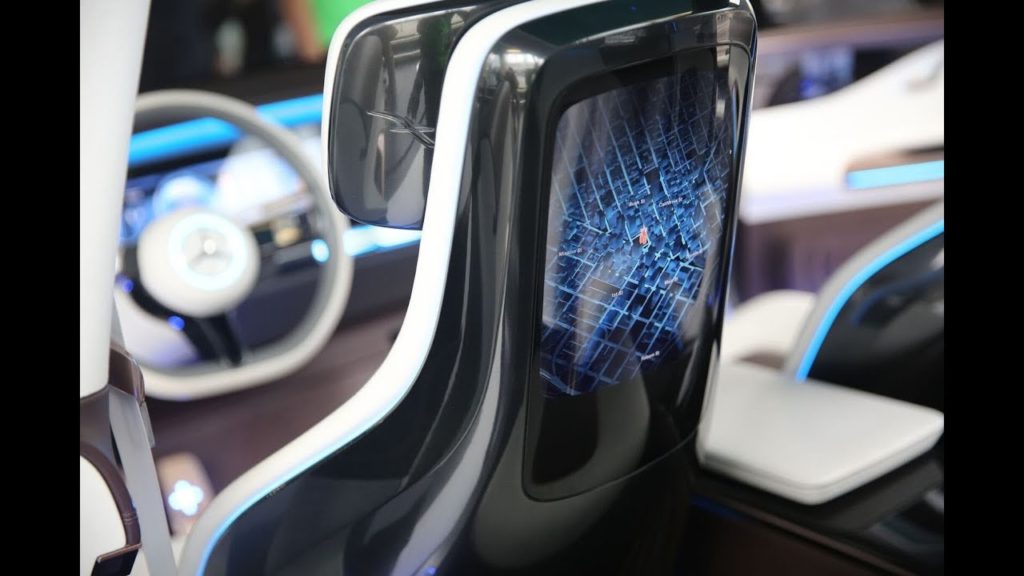

For the automotive sector, Qt offers specialised toolsets such as Qt Automotive Suite and Qt Design Studio, engineered for digital cockpit development and infotainment innovation. These solutions are optimised for 2D and 3D graphics, touch interaction, and advanced multimedia integration, all essential in delivering premium in-vehicle experiences. A notable showcase is Mercedes-Benz’s MBUX infotainment system, built on Qt technology, which exemplifies how the platform supports high-end, safety-critical applications without compromising design freedom or performance.

Qt’s reach extends well beyond automotive. Its technology powers HMIs in consumer electronics, industrial control systems, and medical devices, serving customers in over 70 industries worldwide. Key differentiators include mature rendering capabilities, model-based development workflows, and a broad feature set covering touch handling, multimedia, connectivity, and embedded integration. The company also boasts a strong partner ecosystem, providing solutions for functional safety compliance and industry-specific requirements.

Whether deployed under a commercial license or via its open-source model, Qt delivers reliable long-term support, scalability, and the flexibility to innovate across platforms. For organisations seeking a proven, cross-platform foundation for HMI development, Qt remains a benchmark in both capability and industry adoption.

Candera

Candera GmbH, based in Linz, Austria, is one of Europe’s most established HMI software development companies, with over two decades of experience in embedded GUI development.

At the core of its offering is CGI Studio, a powerful, hardware-independent platform for building advanced automotive and industrial HMIs. It supports rich 2D and 3D graphics, multi-touch interactions, complex state machines, smooth animations, and safety-certified components, making it a strong choice for both infotainment systems and instrument clusters.

CGI Studio stands out for its zero-code design workflows, AI-driven asset importing, and flexible cross-platform runtimes, enabling design teams to go from concept to deployment without deep coding expertise. This technology has been widely adopted across the automotive sector. In fact, many of the world’s top OEMs and Tier-1 suppliers, including Audi and Volkswagen, rely on CGI Studio for their next-generation HMI projects.

Beyond the automotive space, Candera’s solutions are applied in heavy machinery, consumer appliances, industrial automation, and medical devices. Notable demonstrations include LiDAR-enhanced parking visualisations for connected vehicles and advanced e-bike display concepts.

The company also provides dedicated HMI development services to help clients fully leverage CGI Studio in their products. Candera’s strength lies in combining cutting-edge embedded GUI technology with proven industry expertise, making it a go-to partner for brands seeking high-performance, visually refined, and reliable HMI systems.

Siemens

Siemens AG, headquartered in Munich, is one of the most recognisable names among HMI software companies, bringing decades of industrial automation expertise to its comprehensive SIMATIC HMI and WinCC portfolio. These solutions are the backbone of countless industrial operations worldwide, offering everything from entry-level touch panels to advanced PC-based SCADA systems such as WinCC Professional and the modern WinCC Unified platform, a web-enabled, scalable SCADA/HMI environment seamlessly integrated into the TIA Portal engineering framework.

The SIMATIC HMI ecosystem is engineered for robust, real-time plant and machine visualisation. It supports high-resolution graphics, complex scripting for animations, alarm and event management, and full Industrial Internet of Things (IIoT) connectivity. Its native integration with Siemens PLCs, drives, and the cloud-based MindSphere platform creates an end-to-end digitalisation pathway, enabling predictive maintenance, energy optimisation, and Industry 4.0-ready analytics.

Siemens’ HMIs are deployed across a vast range of industries: from automotive manufacturing lines and chemical processing plants to energy utilities and building automation systems. For example, SIMATIC panels play a mission-critical role in automotive assembly lines and municipal water treatment facilities, where uptime, reliability, and intuitive operator interfaces are non-negotiable.

What sets Siemens apart is its tightly coupled hardware–software approach. The TIA Portal unifies HMI configuration with PLC programming, reducing engineering time and ensuring seamless operation across the control stack. This, combined with Siemens’ focus on scalability, from standalone machine panels to fully distributed SCADA architectures, makes the company a trusted partner for organisations needing a future-proof, globally supported HMI solution.

Schneider Electric

Schneider Electric, headquartered in Rueil-Malmaison, is a global leader in energy management and industrial automation, with a strong presence among HMI software companies.

Its HMI/SCADA portfolio sits under the EcoStruxure architecture and includes recognised brands such as Magelis and Vijeo. Key software tools include EcoStruxure Operator Terminal Expert, the modern design environment for Harmony HMIs, and EcoStruxure Machine SCADA Expert (formerly Vijeo XL), a powerful SCADA/HMI platform for machine-level and plant-wide control. The long-established Vijeo Designer remains a go-to screen editor for Magelis industrial PCs and panel HMIs.

Schneider’s HMI software provides a rich set of capabilities: graphical screen design, advanced animation, multimedia integration, web-based visualisation, and native connectivity to the EcoStruxure IoT platform for remote monitoring and analytics. Harmony and Magelis panels are engineered for rugged, real-world environments, operating reliably in everything from water treatment facilities and HVAC-equipped buildings to manufacturing lines and power distribution networks.

Notable use cases include packaging lines for brands like Lindt and Nestlé, automotive painting lines, and building management systems delivered in partnership with companies such as Johnson Controls. With support for PC, Linux, and Windows-based targets, Schneider ensures flexibility across deployment scenarios.

Key differentiators include:

- Tight integration with EcoStruxure for a true controller-to-cloud pathway

- Ease of use through intuitive drag-and-drop editors and gesture controls on newer panels

- Scalability from standalone operator terminals to connected, cloud-enabled SCADA deployments

By combining rugged hardware, user-friendly engineering environments, and deep IoT integration, Schneider Electric delivers HMI solutions that are as practical on the plant floor as they are strategic in the boardroom.

ABB

ABB, headquartered in Zurich with B&R Automation as its Austrian subsidiary, is a major force in industrial automation and a notable name among HMI software companies.

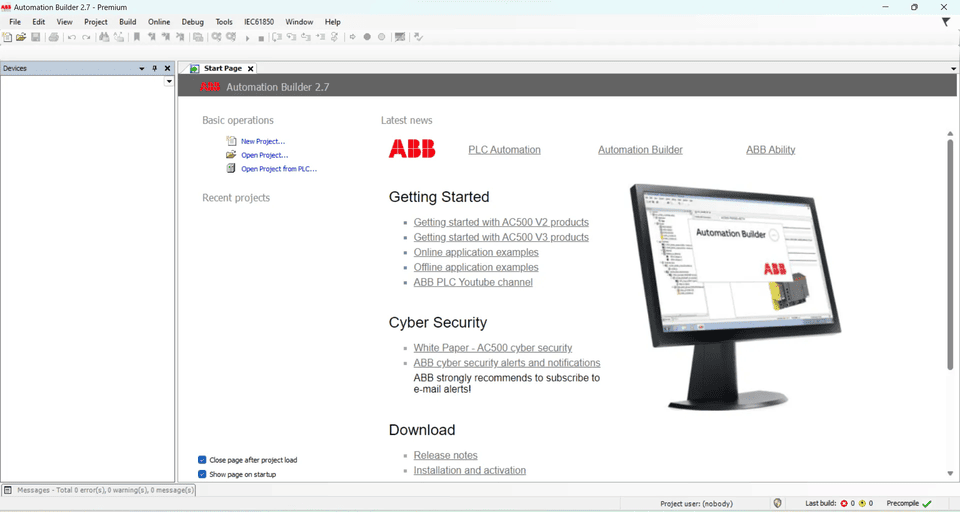

Its Automation Builder platform is an integrated engineering suite that unites PLC, drive, HMI, and motion control development in one environment. Within this ecosystem, HMI configuration sits alongside CoDeSys-based PLC programming, system simulation, and motion setup, enabling engineering teams to work in a single, cohesive workflow.

ABB’s HMI tools support graphics-rich, multilingual touch interfaces suitable for demanding industrial contexts. The company’s solutions span diverse sectors: robotics (with ABB RobotStudio providing immersive visualisation), energy (SCADA for substation control rooms), marine (engine and bridge control panels), and manufacturing (textile and automotive production lines).

A key advantage is ABB’s unified automation stack where control logic, drive parameters, and HMI functions can be developed and tested together. Built-in simulation capabilities allow complete system verification before deployment, reducing commissioning time and risk.

Since acquiring B&R, ABB’s portfolio now also includes Automation Studio (B&R’s HMI/SCADA engineering tool) and a range of industrial-grade hardware such as the Automation Panel 600 series. This combination broadens ABB’s reach from machine-level operator panels to enterprise-scale SCADA deployments.

Key differentiators include:

- Single engineering environment for PLC, drives, HMI, and motion

- Reusability of PLC control logic directly within HMI applications

- End-to-end simulation for faster commissioning and improved reliability

- Expanded hardware and software choice through the B&R product line

With its integrated approach, ABB offers more than just HMIs – it delivers a seamless automation ecosystem that aligns hardware, software, and engineering processes into one strategic platform.

ICT Group

ICT Group, headquartered in Ede, brings deep engineering know-how to the HMI/SCADA space with Iris SCADA, a highly adaptable platform that has earned the company a place among Europe’s most specialised HMI software companies.

Iris SCADA delivers all the core capabilities you’d expect: process visualisation, alarm and event handling, trending, and data logging, while also offering an open database architecture for custom reporting and integration. Designed for long-term reliability and scalability, it protects clients’ investments in automation systems that must perform for decades.

This platform’s robustness is legendary: it was first deployed during the rescue of the Russian submarine Kursk in 2001, where operational stability was critical under extreme conditions. Today, there are over 500 Iris SCADA installations worldwide, serving industries such as heavy lifting (ports, cranes), manufacturing (packaging lines), and oil and gas (offshore rigs and refineries).

Notable clients include:

- Mammoet, global leader in engineered heavy transport and lifting

- Leading offshore operators in oil and gas

Key differentiators:

- Native Dutch engineering expertise with strong local and regional support

- Specialisation in non-standard automation environments, from oil rigs to custom machinery

- Proven reliability in mission-critical and high-risk projects

- Consulting and managed services that wrap around Iris SCADA for complete lifecycle support

With its track record in extreme, high-stakes projects and its flexible, integration-friendly design, ICT Group demonstrates how targeted expertise can compete alongside global HMI software giants.

AVEVA

From its roots in Schneider Electric’s Wonderware and the UK’s original AVEVA, this Cambridge-based global player stands among the most recognisable HMI software companies in the industrial automation landscape.

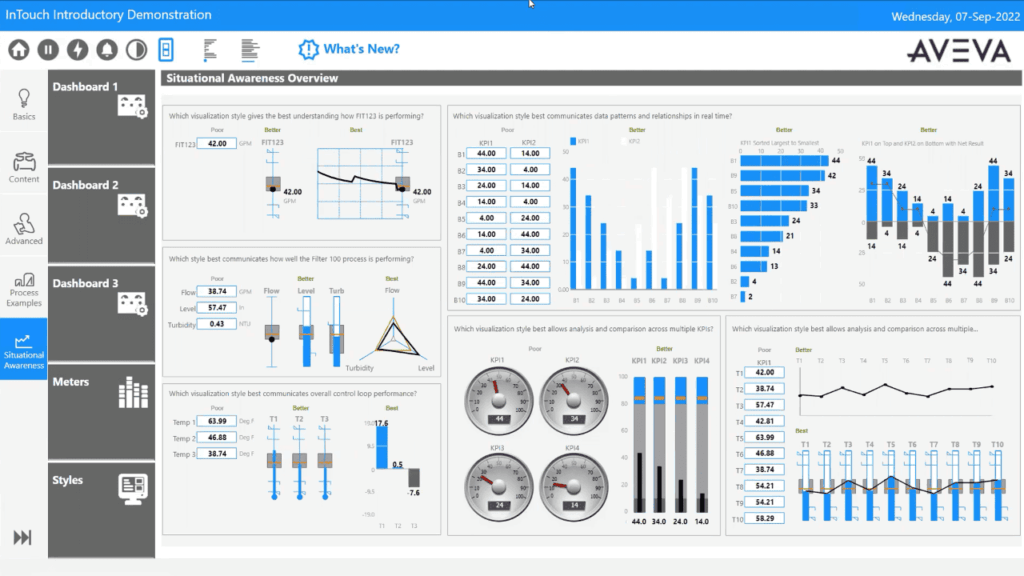

Its flagship HMI/SCADA product, AVEVA Edge (formerly InduSoft Web Studio), delivers a scalable, modern platform for PC-based systems, industrial panels, and embedded devices.

Built on HTML5 web runtimes, AVEVA Edge enables seamless cross-platform deployment, meaning you can design once and run anywhere. Whether it’s a smartphone, tablet, panel PC, or embedded controller, operators get a responsive, consistent interface. AVEVA describes it simply: publish for nearly any device, monitor and control from virtually anywhere.

The platform’s interoperability is one of its strongest differentiators. It integrates natively with AVEVA’s wider industrial software portfolio and supports hundreds of PLC protocols out of the box. This makes it equally at home in a utility SCADA network for gas distribution as in shop-floor dashboards for automotive assembly lines.

Key industries:

- Process industries: water treatment, energy, pharmaceuticals

- Manufacturing: food & beverage, automotive, electronics

Notable capabilities:

- Broad vendor connectivity and fully open architecture

- Unified HMI, SCADA, and OEE (Overall Equipment Effectiveness) dashboards in one environment

- Flexible licensing model including subscriptions

- Rich feature set for mission-critical systems: security, version control, scripting, and high-availability support

With its mix of global reach, proven industrial expertise, and future-ready architecture, AVEVA Edge positions itself as a go-to choice for organisations that demand both scale and adaptability in their HMI systems.

Bosh Rexroth

Bosch Rexroth, based in Lohr, delivers next-generation operator experiences through its ctrlX AUTOMATION platform, positioning itself as one of the most forward-thinking HMI software companies in the industrial automation space.

The ctrlX HMI framework is built entirely on open web technologies, meaning any HTML5-capable device, from embedded industrial PCs and multi-touch panels to tablets and desktop browsers, can run the same interface without hardware constraints. This platform independence empowers manufacturers to scale visualisation from entry-level operator panels to high-performance control-room setups with minimal engineering overhead.

Rexroth’s hardware lineup includes rugged multi-touch web panels and panel PCs optimised for both mobile use and direct machine-mounting. Real-world applications range from CNC machine control dashboards to factory-floor operator terminals in discrete manufacturing.

By removing the dependency on proprietary hardware and offering a rich ecosystem of extensions, Bosch Rexroth enables agile, cross-platform HMI deployments that adapt to evolving industrial requirements.

Key differentiators:

- Hardware-agnostic HMI framework that runs consistently across devices

- CDI+ cable technology combining touch input and video in a single connection for cleaner installation

- ctrlX World marketplace, enabling customers and partners to add bespoke HMI widgets and apps

- High configurability and future-proof design via web standards

By removing the dependency on proprietary hardware and offering a rich ecosystem of extensions, Bosch Rexroth enables agile, cross-platform HMI deployments that adapt to evolving industrial requirements.

Beckhoff Automation

Beckhoff, headquartered in Verl, is a pioneer of PC-based automation and a recognised innovator among HMI software companies. Its TwinCAT suite brings control, motion, and HMI development under one roof with TwinCAT HMI offering a uniquely open, web-first approach to industrial visualisation.

Designed directly within Microsoft Visual Studio, TwinCAT HMI lets engineers create operator interfaces using a drag-and-drop WYSIWYG editor while still having access to the full depth of professional development tools. Built on HTML5 and JavaScript, it runs responsively on any operating system, browser, or device, from shop-floor panels to mobile devices and control-room displays.

This scalability makes it suitable for a wide range of applications: building automation (smart control dashboards), packaging machinery (intuitive operator panels), and energy systems (multi-user supervisory HMIs).

Key differentiators include:

- Native integration with Beckhoff’s EtherCAT-based controllers and TwinCAT PLCs

- Full Visual Studio tooling for streamlined engineering and debugging

- Highly modular architecture supporting standard controls and custom widgets

- Open, web-based framework for future-ready, cross-platform HMI deployment

By combining a flexible, browser-based front end with powerful PC-based control, Beckhoff delivers HMIs that are not only high-performance but also inherently adaptable, ideal for manufacturers seeking long-term, standards-driven visualisation solutions.

About the author