Marine HMI:

Yacht control panel

Production-ready, customisable, maritime HMI accelerator that brings propulsion, navigation, power and alarm systems together on one rugged, gesture-friendly touchscreen.

Technology stack

Built for shipbuilders, system integrators and luxury yacht OEMs, our yacht control panel provides a single, intuitive interface for real-time monitoring and control in the most demanding marine environments.

Delivered as a one-time purchase with deployable assets, protocol stacks, and branding-ready UI components, it offers a fast route from prototype to bridge installation.

Key features

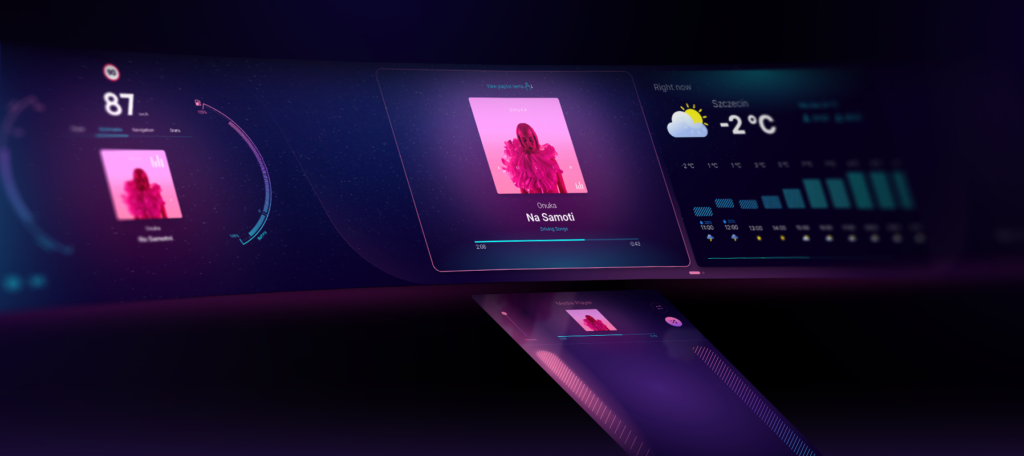

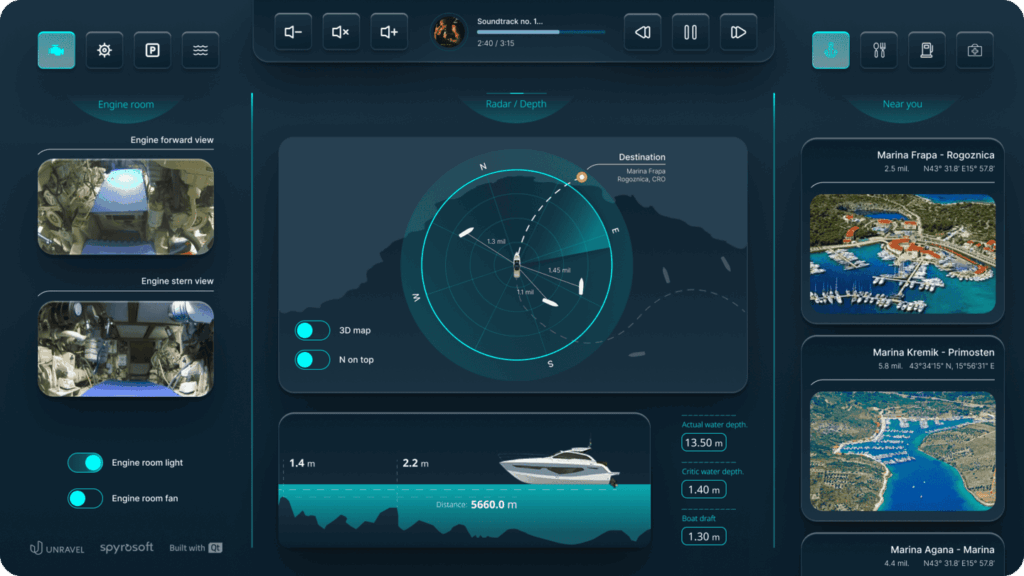

Unified situational awareness

Monitor propulsion, navigation, tanks, power and alarms on a single, high-contrast dashboard. Get the information that matters, exactly when it matters.

Designed for motion

Large touch targets and gesture-friendly controls ensure safe operation in rough seas and with gloved hands, reducing cognitive load for captains and crew.

Fast integration

Pre-configured Qt/QML templates and protocol stacks for NMEA-2000, SeaTalk and NavNet shorten integration time dramatically. Typical projects reach onboard validation in about one month.

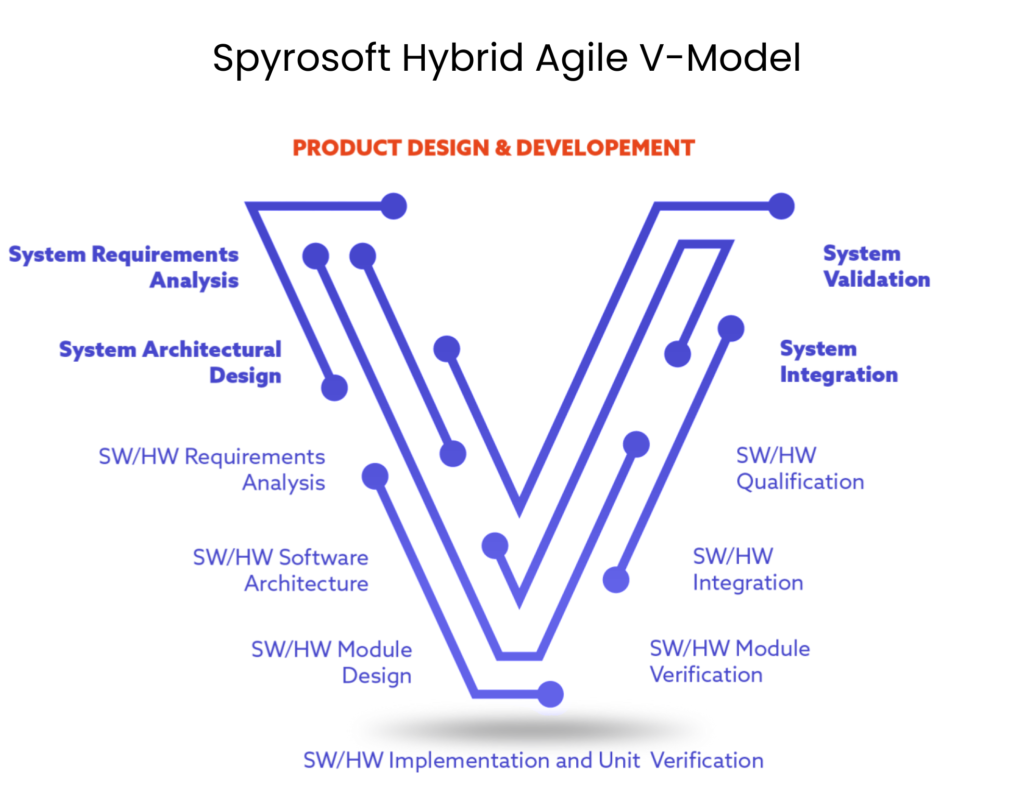

Proven quality processes

Manual and automated Squish tests are embedded in the CI/CD pipeline. Each build is verified in Dockerised test environments to guarantee stable, regression-free releases.

OEM-ready customisation

Every layout, colour scheme and widget can be rebranded quickly using Figma and Qt/QML components — keeping visual consistency across product lines.

Single-payment delivery

Delivered as a one-time licensed package with full source templates, Figma design files and test suites — not a subscription service.

Safety and compliance

Secure process logging, redundancy, and compatibility with industrial and maritime automation systems ensure long-term reliability.

How does it work?

Deploy

Receive the complete accelerator package: source templates, Figma files, Squish suites, and protocol adapters. Install on your SBC or integrator hardware.

Connect systems

Link NMEA-2000, CAN, or ModBUS networks and validate data flow using provided connectors.

Customise UI

Apply OEM branding and modify layouts in Qt/QML and Figma typically within five working days.

Test and validate

Execute Squish automated tests and manual checks. Integrate into your existing CI/CD pipelines.

Commission

Conduct field trials, final calibration and handover. Ownership is transferred at delivery. No ongoing licensing.

What’s inside?

Real-time performance dashboards

Conduct field trials, final calibration and handover. Ownership is transferred at delivery – no ongoing licensing.

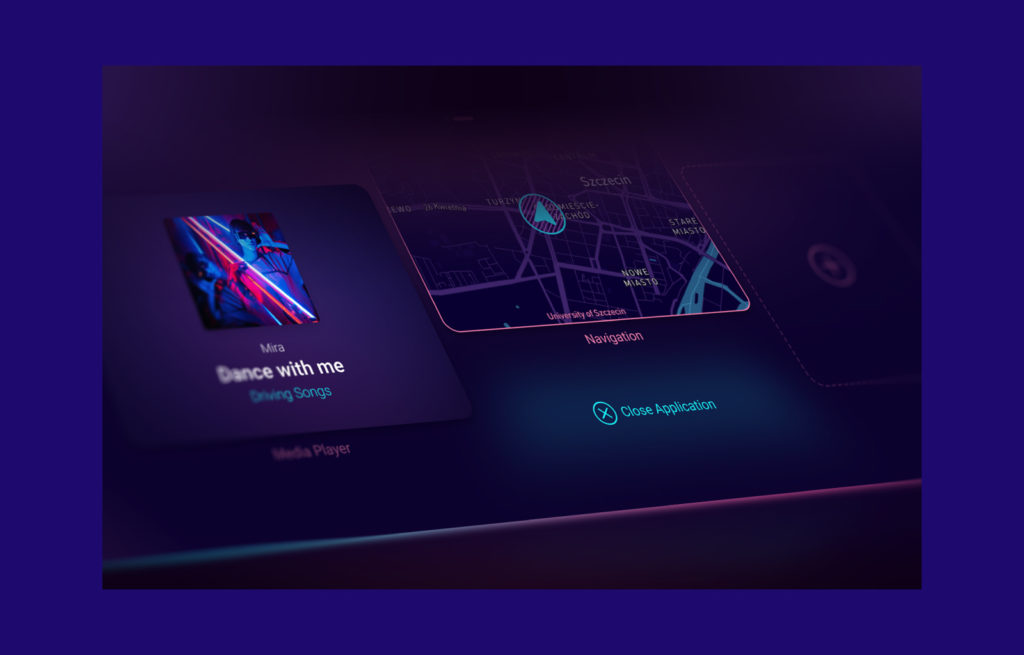

Navigation and routing module

Integrates live GNSS, chart overlays and route planning with native NMEA-2000 data ingestion. Gesture-based map controls enable quick panning and zooming without precision taps.

Alarm and event management

Visual and audible escalation with prioritised alerts and historical logs. Interaction flows are optimised for gloved use and motion, ensuring fast, confident responses during incidents.

Role-based layouts

Separate, configurable dashboards for captain, crew and engineers. Figma templates and modular QML components make branding and role changes straightforward.

Hardware and connectivity support

Includes ready-made connectors for NMEA-2000, SeaTalk, NavNet, ModBUS and CAN. Compatible with redundant Ethernet, RS232/RS485, and removable storage for compliance logging.

Developer and QA toolkit

Full Qt/QML source, editable Figma files, and Dockerised Squish test suites. Integrate directly with GitLab CI for automated regression testing and continuous delivery.

Accelerator performance metrics

-

System integration (with NMEA/CAN)

≈ 1 month (depends on vessel class and configuration)

-

Input-to-feedback latency

< 60 ms

-

OEM branding and layout configuration

< 5 days

-

Uptime during testing

≥ 99.7%

Ideal use cases

The Maritime HMI Accelerator serves as the digital bridge for any onboard system requiring reliable human–machine interaction.

Ballast Water Management Systems

Monitor, treat and document ballast operations in full compliance with the IMO Ballast Water Management Convention. The HMI logs treatment data securely and supports automated reporting.

Bilge and fluid management

Track and control bilge, fuel and wastewater pumps in real time. Integrated alarm management ensures no discharge occurs without proper treatment.

Anti-heeling control

Balance cargo load and maintain stability automatically. Gesture-friendly controls allow precise ballast adjustments even during motion.

Thruster and propulsion systems

Operate bow and stern thrusters from an intuitive, moisture-resistant Glass-Film-Glass panel interface. Designed for outdoor exposure and fast reaction in docking manoeuvres.

Environmental and hardware compliance

Operating temperature: −20 °C to +60 °C

Ruggedised GFG touch panels, glove-friendly

Redundant Ethernet and serial connectivity (CAN/RS232/RS485)

Removable SD/USB storage for long-term data logging

Secure process logging and redundancy for maritime automation standards

Transitioning from legacy Windows CE to Embedded Linux or Windows Embedded Standard 7 offers smoother graphics, higher performance and improved system clarity.

Safety and quality

Spyrosoft’s maritime HMIs are developed under functional-safety-inspired processes aligned with:

ISO 26262 (for software safety principles)

Automotive SPICE and IEC 61508

QA automation with Squish GUI Tester and GitLab CI/CD

Every accelerator build undergoes extensive simulated sea trials, meeting ≥ 99.7 % uptime in testing.

contact us

Simplify integration. Shorten certification. Deliver a safer, smarter cockpit for your next vessel.

Clients say about us

A microHMI is a modular architecture where UI features are delivered as independent, lightweight components. It speeds parallel development and simplifies branding.

Squish simulates real user interactions across your Qt widgets and QML. It validates behaviour end to end and integrates with CI to gate merges on test results.

Yes. We support efficient on-device models for low latency and privacy, with a cloud fallback where connectivity and feature scope allow.

We align requirements, verification and safety cases with your process, using traceable artefacts and automated testing to maintain compliance.

The reference is Qualcomm SA8155P on AAOS. We can assess and port to other AAOS-capable platforms.