IoT in Industry 4.0

The Internet of Things is one of the backbones of the fourth industrial revolution (also known as Industry 4.0). With the price of IoT sensors dropping to a historic low (by 200% since 2004) and off-the-shelf solutions available, it’s now easier than ever to increase digitalisation in an organisation of any size from the Industry 4.0 sector.

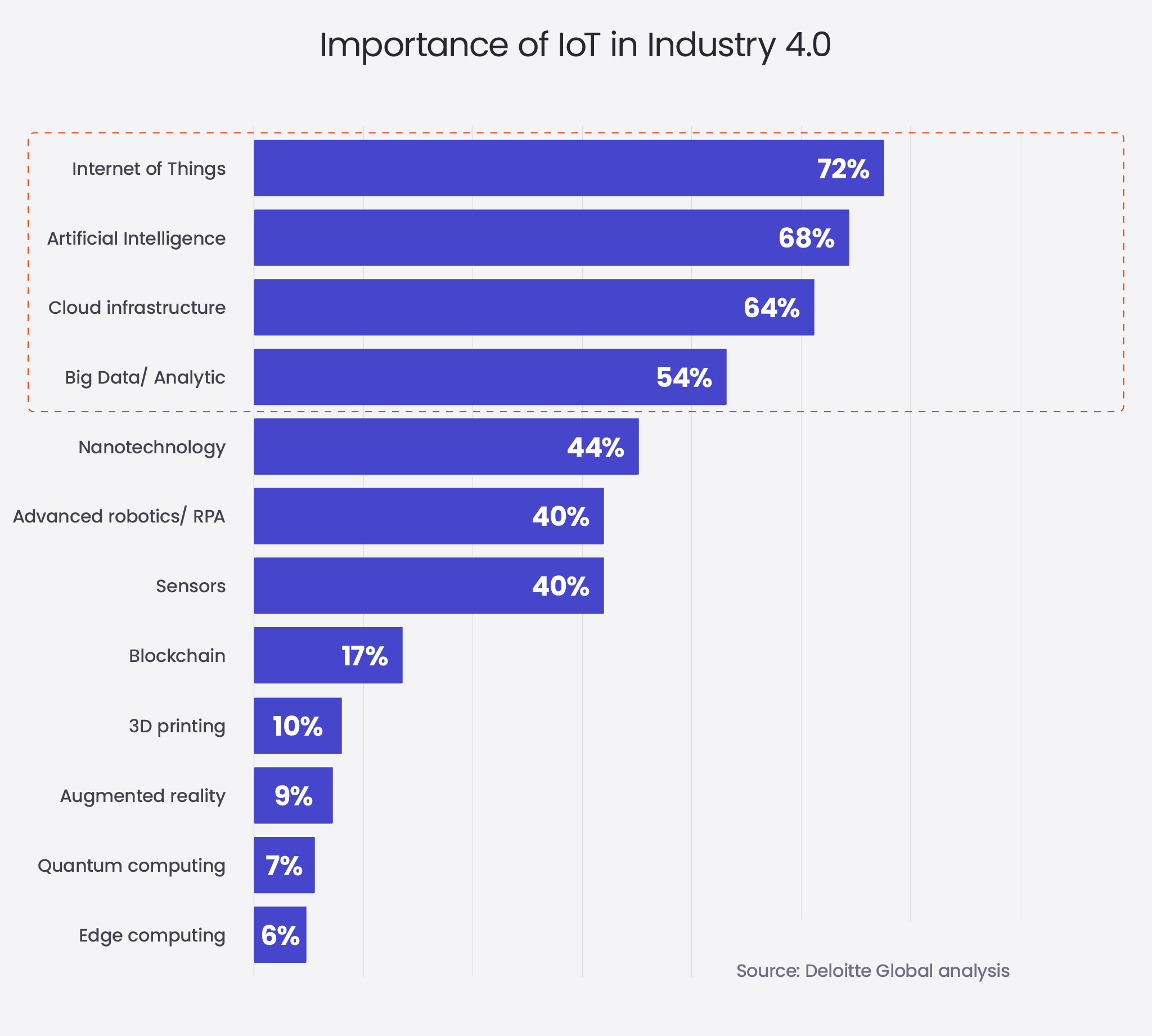

According to Deloitte’s survey, the majority of CXO working in Industry 4.0 agree that IoT will be the technology with the biggest impact on their organisation over the next few years alongside other ‘big four’ technologies in the sector (Internet of Things, Artificial Intelligence, Cloud infrastructure and Big Data).

In this guide, we’ll take a closer look at the IoT in the Industry 4.0 context. You’ll learn:

- how IoT architecture looks like,

- what IoT hub is and how it’s used in Industry 4.0,

- the process of building and managing IoT Systems,

- how various IoT connectivity technologies compare and how to choose the right one for your needs,

- how to keep your IoT solution safe from hacker attacks.

Let’s dive in.

What is the Internet of Things, and how it’s used?

The Internet of Things can be defined in many different ways, but the easiest definition to understand is this one: every electronic device that has the following four functions: connect, collect, analyse and transform, is an Internet of Things device. When you have a device (be it a sensor, a lightbulb or a fridge) and you connect it to a network (i.e., Wi-Fi), this device can collect data from our environment – metrics that we can further analyse.

Download our guidebook to IoT in Industry 4.0

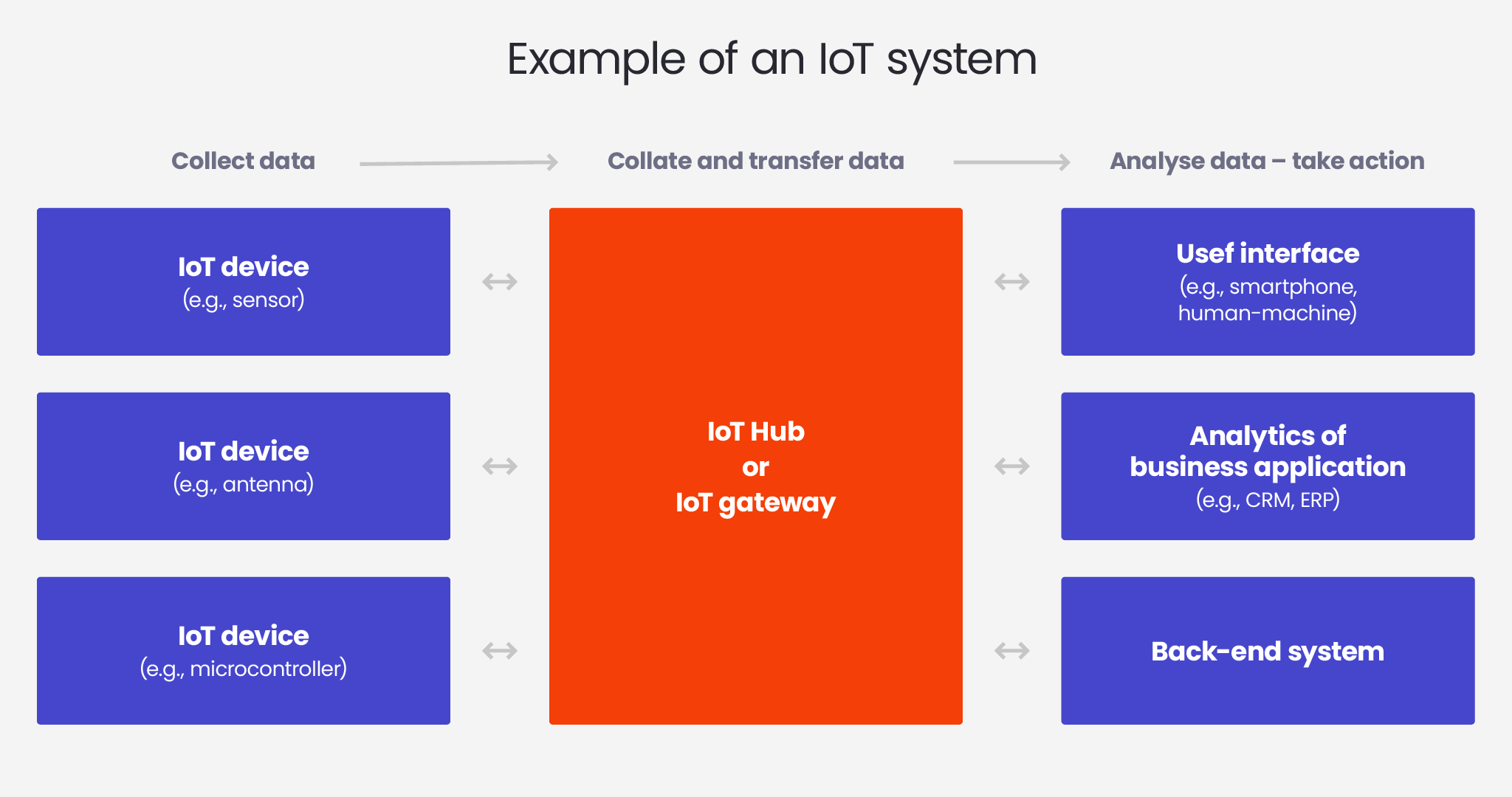

Get the ebookBy placing IoT sensors on the devices, you can collect the data, i.e., about the temperature, air quality, etc., and it is then transferred to the Cloud where it’s made available to different applications that can use the data and process it. Please note that the communication between the devices and the applications can be bi-directional: devices can be managed via external applications, i.e., for access management purposes.

Data collection is the most common use of IoT, but the Internet of Things devices can be used to provide different services, e.g., remote vehicle monitoring, including the vehicle location and its route. Another use case is a smart building with multiple devices, or industrial machines managed using steering algorithms.

Learn more about why the Internet of Things increased in popularity and how it has changed over the last five years.

Let’s now take a closer look at what an IoT system looks like layer by layer. It’s crucial to have a good understanding of IoT architecture to avoid common mistakes, like inaccurate estimations or no clear plans on where the data should be processed.

What is IoT architecture?

When you think about the IoT architecture in general, you may imagine it as a machine with multiple cogs that have to work together in order for the whole system to function as intended. Please note that when you plan it, you should include not only the physical components but also the data formats that will be used, organisational procedures and the business context of the system.

As a rule, and in order to function without fail, the IoT architecture has to include these four building blocks:

- Scalability

- Maintainability

- Functionality

- Availability

All of these are crucial, with scalability considered the most important for growing organisations with the increasing number of projects to be managed via IoT architecture.

Four stages of the IoT architecture

Once you start putting an Internet of Things system together, there are four stages or layers you should include. Please note that these layers also represent the data processing process.

Advanced data analytics tools play a crucial role in these stages, allowing businesses to collect, analyse, and interpret vast amounts of data in real time.

1. Sensors and controllers

The first layer can also be described as all of the devices that are connected to the network. This can include but is not limited to sensors that collect data such as temperature, movement and air quality, and controllers that can be used to steer the devices and send requests to them. These can alter physical reality – i.e., they can open doors, switch on alarms in case of fire or property infringement or stop an assembly line. Once the sensors collect the data, they can send it to the network for processing.

2. Network

The Data Acquisition System (DAS) and gateways represent the network layers. DAS is used for aggregating and converting raw data into formats accessible for all layers of the system. Gateways work as a connecting level between the sensors and the Internet, but they can also complete basic functions such as data filtering and malware prevention.

3. Applications and edge IT

This layer consists of any element that uses the collected data in any shape or form. It could be Machine Learning tools, a data visualisation technology or an external system that inspects and evaluates everything happening at a plant or a public property. This layer also includes applications that can send information to the networked devices or manage them in any way.

4. Cloud or data centre

This is where the correctly formatted and processed data is stored and can be further analysed. This can also mean that the Cloud or the data centre needs to be supplied with information from other sources outside of the IoT system. Depending on the volume of data you need to keep and process, using the Cloud, such as Microsoft Azure Cloud or Amazon Web Services, may be an ideal solution.

What are the common mistakes when planning IoT architecture?

According to Jaroslaw Dzikowski, who works as a Senior Embedded Software Engineer at Spyrosoft, there are four crucial challenges in introducing the Internet of Things into your organisation:

- Unclear requirements

- Inaccurate estimations about the foundational elements of your system

- No clear definition of where data should be processed

- Not enough accounting for remote firmware upgrades

It is essential to align IoT architecture with business processes to ensure better coordination, visibility, and analytics across various business functions.

Want to learn more about IoT services? Check our offering

Learn moreWith the dominant role of IoT and data collection in the Industry 4.0 sector, there’s one element of the IoT system that will be crucial for the further development of this area: the IoT hub.

Below, you’ll find out what an IoT hub is, what off-the-shelf IoT solutions are currently available, and what’s the process for introducing IoT hubs on the organisational level. The following section was written in collaboration with Spyrosoft’s Lead Embedded Architect, Krzysztof Maciejewski.

What is an IoT Hub?

IoT hub is a Platform-as-a-Service (PaaS) managed service and can be used as a focal point that allows devices to be connected to the Internet. On one side, there are the devices that send their data from the sensors to the hub and/ or receive the information from the hub. On the other side, there are applications that may or may not be Cloud-based and that can manage the devices and process the data, i.e., to visualise it. In short, the IoT hub serves as a mediator between these devices and the applications that are used to manage the former and to collect data.

In the context of Industry 4.0, digital transformation plays a crucial role in enhancing manufacturing processes and operational efficiency by unifying data and systems, creating more intelligent and automated operations.

This solution can be developed independently, but there are ready-made products that are available on the market (full list below).

IoT Hubs available on the market

The most common IoT Hub solutions are:

- Azure IoT Hub

- IBM Watson IoT Platform,

- AWS IoT Device Management,

- ThingsBoard,

- AWS IoT Device Defender,

- Trend Micro Deep Security,

- Cumulocity IoT,

- Scaleway IoT Hub.

What are the benefits of using IoT Hubs?

Security

Most of the solutions available on the market have at least a few ways to manage who and what devices can access them, with the ability to build a device registry into the hub, distribute shared access signatures using access keys and security tokens and API integrations aimed at increasing the security of these solutions.

Full control over the process

Once you’ve completed the IoT hub implementation process I’ll mention below, you can precisely control what devices are interconnected, what data they collect and share (be it with each other or external applications) and where the data are stored and processed.

Scalability

Regardless of how large or small your IoT networks are right now, by using an IoT hub, you can easily add new devices or even a set of devices or limit their number. Again, with most of the ready-to-use IoT hubs available on the market, you can do it in a matter of minutes.

IoT Hub use cases

Thanks to the IoT hub, businesses from the Industry 4.0 sector can benefit from insights based on data collected from interconnected devices. These insights can be used for:

Predictive maintenance

By analysing the data collected by sensors placed in the machines, the lifespan of crucial parts can now be predicted so that they can be replaced before a failure. Predictive maintenance allows manufacturers to cut down the costs of routine maintenance, which may not always be necessary, as well as reduce the risk of production delays caused by unexpected failures.

Quality control

IoT is also widely used to make quality management more efficient. IoT, together with AI, advanced optics and sensors, is a more accurate, automated way to ensure no faulty product comes off the production line. Based on data collected from cameras and sensors through an IoT hub, AI software learns to distinguish between good and flawed products. When the machine vision system determines that a product has a defect, it’s removed from the production line.

Digital twin

A digital twin is a virtual 1:1 representation of a physical object. It can be used to run simulations for training purposes, examine performance problems and generate valuable insights, for example, on product improvements. The observations and conclusions can then be applied to the original object.

Digital twin technology can be combined with mixed reality. A person, for example, an electrician, can see a virtualised version of an electrical installation through mixed reality goggles or headsets, like Microsoft HoloLens. They can see where the cables are without the need to use an electric wire detector. They can also check all key parameters without specialised equipment as all data is collected in the IoT hub in real-time and displayed right before their eyes through the mixed reality headset.

What is the process of building an IoT system?

The first thing to do is connect all devices to the Internet. If the device already has a connectivity setup installed (more about the connectivity options later on), all you need to do is to bring it online.

The manufacturing process in Industry 4.0 transforms traditional methods through the integration of advanced technologies like the Industrial Internet of Things (IIoT), AI, and machine learning, resulting in enhanced efficiency, real-time monitoring, and reduced downtime.

When you plan for data collection, the second step is to think about what data you may need to collect and then decide where to place the sensors, what type they should be and what software would be best for data aggregation and receiving requests. This stage of the process requires not only thinking about the electronics (sensors) part but also about the mechanics behind the data collection and device steering process. The sensors can also be used to expand the functionalities of a device.

The next step is building a Cloud-based application that can store the data and be used for steering and communicating with the devices.

Once the IoT hub is implemented and ready to use, the next thing to do is to start managing your fleet of devices. Here are some best practices recommended by our Lead Embedded Architect, Krzysztof Maciejewski:

- Use automation as much as possible.

- Automatically discover any internet access problems from the devices and improve the connection if needed.

- Automatically monitor the devices’ health and replace/fix them in case of any failures.

- Use device firmware updates over the air campaigns if needed.

- Easily scale up your solution – adding new devices/new functionalities/introducing the usage of AI/extending Cloud computing.

Read more about building and managing IoT Hub systems >>

Connectivity options

Choosing the right connectivity technology is crucial in building an IoT system. There are a plethora of IoT connectivity technologies that are suitable for specific needs, varying from short-range ones based on RFID to the broadband Internet.

Each technology gives different results and matches specific needs. Below are the criteria that you should take into consideration to choose the most suitable option:

Range

There are close-range technologies, such as RFID, NFC, Bluetooth or Wi-Fi, whose range is measured in feet, and large-range ones, like a mobile network. There’s also satellite connectivity, which has a global range.

Costs

We already mentioned that satellite connectivity is probably the most costly option. Mobile network connectivity largely depends on the amount of data transferred – it can be relatively cheap or pretty expensive. Bluetooth, if used for local network connection and/ or without internet access, doesn’t generate any costs other than the costs of power consumption. If Bluetooth is used to access the internet through a certain gateway, then you must also include the cost of data transfer through such a gateway.

As you can see, the cost of IoT connectivity depends on the range and the size of data transfer to a great extent.

Bandwidth

Bandwidth is closely tied to the range and cost. The more data you want to transfer, the higher the cost and the more difficult it is at close range. For wireless IoT connectivity options, the larger the distance, the slower the data transfer. In the case of wired connectivity options, like ethernet or fibre, the bandwidth is significantly bigger than for wireless solutions. However, also the cost gets higher.

Power consumption

Some connectivity technologies, such as mobile networks, are quite electricity-drawing. It may be a problem when a device is to transmit a lot of data while working on a battery.

However, there are certain technologies that enable the use of one battery for the whole life cycle of a device. In such a case, of course, the power consumption must be minimal. It can be achieved by limiting data transfer and range, which results in significantly lower power consumption but greater latency.

Certain mobile network technologies introduced special sub-standards, like LTE Narrowband IoT. It allows transmitting data at low speed, keeping power consumption at a minimum, so a device may indeed run on one battery throughout its whole life cycle.

Latency

Certain technologies with very small bandwidth consume little power; however, due to low data transfer speed, they have high latency.

Learn more about the most common IoT connectivity options.

How to keep your IoT solution safe from hacker attacks?

The implementation of IoT technology does not always go hand-in-hand with maintaining appropriate security measures. In this section, you’ll learn what the risks are and how to ensure your IoT solution is well protected against them.

Securing the entire supply chain is crucial in IoT implementations, as advanced technologies like IoT and AI enhance visibility, efficiency, and management across the supply chain.

What security risks might you encounter with IoT?

Ransomware threat

A special kind of malware, named ransomware, blocks access to specific files or an IoT device itself by encrypting them until you pay the hackers to give you the decryption key.

DDoS attacks

A botnet is a network of devices connected to the IoT that are infected with malware, which allows hackers to control them remotely. Botnets may be used by hackers to paralyse an organisation, either to get the money or, in some cases, to simply damage a competitor’s business.

PDoS attacks

In the case of a permanent denial of service attack, the goal is to permanently disrupt a device’s functionality or delete all the stored files.

Using your data transfer

Hackers may generate excessive traffic, which could use a significant amount of data transfer. You may only notice that when you get your monthly invoice.

How to improve IoT security and avoid security issues?

There are some crucial recommendations to follow:

- Keep a simple approach to device design.

- Use a private network if possible.

- Ensure regular firmware upgrades.

- Secure data exchange with TLS cryptographic algorithms

Learn about the above recommendations in more detail in this article about IoT security.

Looking for a tech partner to help you build and scale industrial IoT solutions?

At Spyrosoft, we’ve worked with multiple customers from the Industry 4.0 sector, and we have hands-on experience in building and scaling industrial solutions. If you’d like to know about our updated Industry 4.0 offering or need a team of experts to support your IoT project, check more information on our Industry 4.0 website and book a no-obligation call using the form below.

About the author

Contact us