How automating forecasting transforms predictive maintenance into a strategic tool

Predictive maintenance is becoming a fundamental component of smart business strategy. As automotive systems become more complex and interconnected, the ability to anticipate failures before they happen has evolved from a technical nice-to-have into a priority.

We’re witnessing a significant shift: forecasting is now being automated. Machine learning models analyse vast streams of telemetry and historical data in real-time, identifying patterns that no human could detect fast enough.

What was once reactive becomes proactive – and once isolated data points become connected for improved decision-making.

In this article, you’ll discover how automated forecasting turns predictive maintenance into a strategic asset, and what it means for your business. Let’s dive in.

Introduction to predictive maintenance

Predictive maintenance is a proactive approach to maintenance that uses advanced technologies, such as machine learning and predictive analytics, to analyse historical data and real-time data from sensors.

This approach enables organisations to predict when equipment is likely to fail or require maintenance, allowing them to take preventive measures before issues arise. By utilising predictive maintenance software, you can significantly reduce maintenance costs, minimise downtime, and optimise resource allocation.

The true cost of staying reactive

Traditional maintenance models rely on fixed schedules or, in some cases, emergency interventions. In both scenarios, organisations become trapped in a cycle of inefficiency.

You’re either over-maintaining assets and wasting resources or reacting too late to failures that could have been avoided.

What’s often overlooked is the hidden, organisational cost of this inefficiency:

- Engineering receives only partial insights rather than complete failure narratives.

- Operations teams struggle to reallocate vehicles or personnel.

- Procurement faces urgent, last-minute sourcing requests.

- Finance departments deal with unpredictable cost spikes and missed budget targets.

In contrast, predictive maintenance – supported by automated forecasting – brings cohesion across departments. It gives everyone the visibility needed to take action before issues arise.

What’s important to note, in an enterprise context, those costs are not solely financial. They can also affect customer satisfaction, brand trust, and your ability to scale effectively.

Discover our predictive maintenance expertise

Learn moreFrom raw data to intelligent forecasting

Mining historical data to predict what’s next

The journey to predictive maintenance doesn’t start with advanced technology, but rather with the historical data that you already have.

Years of maintenance records, repair histories, failure reports, and usage statistics often sit untouched and fragmented across various systems or departments. When you consolidate and analyse these pieces of legacy data using machine learning models, they become something far more powerful: a foundation for intelligent forecasting.

Value is hiding in places you didn’t expect, e.g. in warranty claims, sensor logs, driver-reported issues, and even service desk tickets. When unified, these sources reveal the story behind system wear, degradation, and risk.

By automating the analysis of historical patterns, organisations can move from reactive reporting to generating probability-based insights. This allows them to identify weak signals before they escalate into failures. The forecasting process becomes a critical element for businesses to anticipate future trends and make swift, informed decisions.

To sum up: it’s not about acquiring more data, but about making existing data work smarter. That shift can change everything.

AI & machine learning in predictive maintenance software

The real power of predictive maintenance lies in recognising patterns hidden in data.

Artificial intelligence and machine learning excel at processing vast amounts of both real-time and historical data, identifying the early indicators of potential failures that even the most experienced engineers might miss. This analysis occurs at scale – monitoring thousands of vehicles simultaneously.

Here’s how intelligent forecasting works in practice:

- Supervised learning models draw on labeled historical data to spot recurring failure patterns.

- Unsupervised learning continuously scans live telemetry to detect anomalies and the subtle signs that something is off.

- The more data it ingests (from terrain type and climate conditions to driver behaviour and usage intensity), the smarter it becomes.

Over time, these systems provide detailed insights such as:

- “Brake system failure risk increasing by 40% in vehicles primarily used on steep terrain.”

- “Transmission wear patterns are accelerating after 30,000 km in stop-and-start urban conditions.”

- “Failure is likely within 14 days: pre-emptive maintenance is recommended.”

You can treat them as strategic signals, giving you the chance to intervene early, make smarter plans, and mitigate risks long before anything breaks.

Sensor data: the fuel behind the forecast

Predictive maintenance models are not built in isolation. They rely on a continuous stream of telemetry data, which consists of real-time signals that reveal how a vehicle is driven, where it operates, and under what conditions.

Data paints a detailed picture of vehicle health in context. Of course, the richer and more frequent the telemetry data, the sharper the forecasts.

The types of sensor data utilised include:

- Terrain type – urban, highway, off-road.

- Speed and RPM fluctuations – spikes, drops, inconsistencies.

- Component-level temperature readings – risks of overheating.

- Usage frequency and idling time – wear associated with overuse or underuse.

- Driver behaviour patterns – aggressive acceleration, braking, or sharp handling.

When this live telemetry is correlated with historical performance trends and failure patterns, the model gains situational awareness. It adapts, it evolves, and it delivers forecasts that are accurate and actionable.

And since telemetry data is often already being collected, you don’t have to start from scratch; you can unravel insights that are already within your reach.

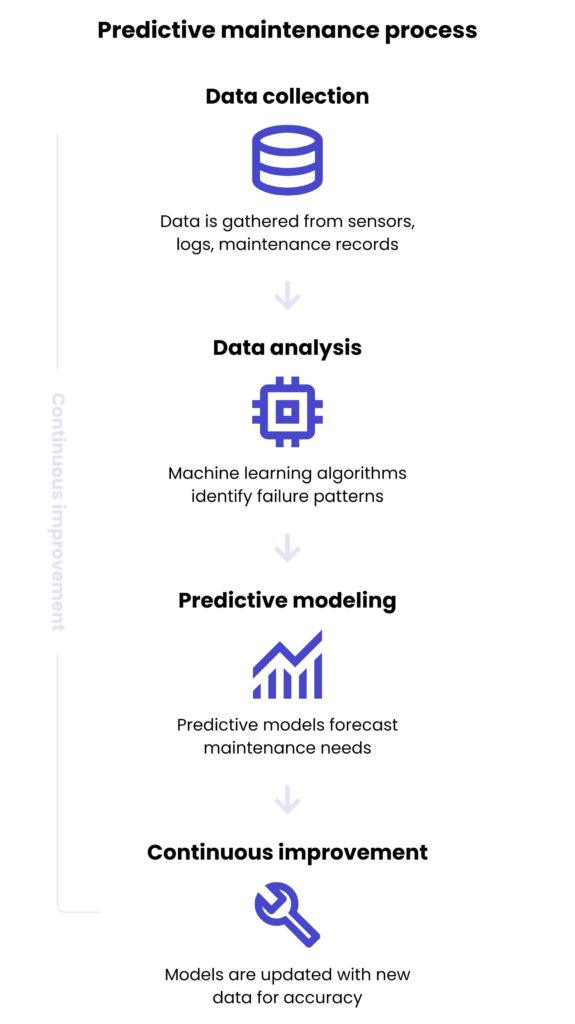

Predictive maintenance process

The predictive maintenance process involves several critical steps, starting with data collection. You gather data from various sources, including sensors, equipment logs, and maintenance records.

Once the data is collected, it’s analysed by machine learning algorithms and predictive analytics. By recognising failure patterns, organisations can create predictive models that forecast when equipment is likely to require maintenance.

Predictive models are continuously updated with new data to ensure that predictions remain accurate. This ongoing process of data collection, analysis, and model updating is streamlined by predictive maintenance solutions, such as automated forecasting. These tools provide actionable insights to maintenance teams.

By leveraging machine learning algorithms and predictive analytics, organisations can transform their maintenance strategies. This not only reduces downtime and maintenance costs but also enhances overall asset reliability and performance.

Closing the feedback loop

One of the most valuable (and overlooked) aspects of predictive maintenance is its potential to create a feedback loop that enhances both systems and strategy.

Turn data into business impact

See what we offerFor example, once forecasts are compared with actual outcomes (e.g. predicted failures vs. real failures), the model improves. This improvement extends to your operational playbook, impacting areas from parts stocking to vehicle design.

This leads to a compounding effect: fewer breakdowns, better data quality, smarter decisions, stronger predictive models.

Connecting the dots across departments

The good news is that predictive maintenance doesn’t just benefit the maintenance department.

It fosters cross-functional collaboration, eliminating silos and enhancing alignment across the business operations. At its core, automating forecasting introduces a shared language of insight – one that every team can act on immediately.

Curious about what this looks like in practice?

- Engineering receives feedback from the field, i.e. data on how components behave in different conditions, feeding back into smarter design and testing processes.

- Operations can schedule with confidence, minimising downtime and optimising asset availability (no more last-minute repairs or unexpected shortages).

- Procurement orders proactively, sourcing parts and services based on predicted demand.

- Finance gains cost predictability and control over budgets.

- IT and Data teams collaborate with stakeholders to integrate clean data pipelines, telemetry feeds, and ML models that drive real business outcomes.

Instead of reacting to failure, your entire organisation becomes proactive and aligned around a common layer of predictive intelligence.

Predictive, proactive, profitable

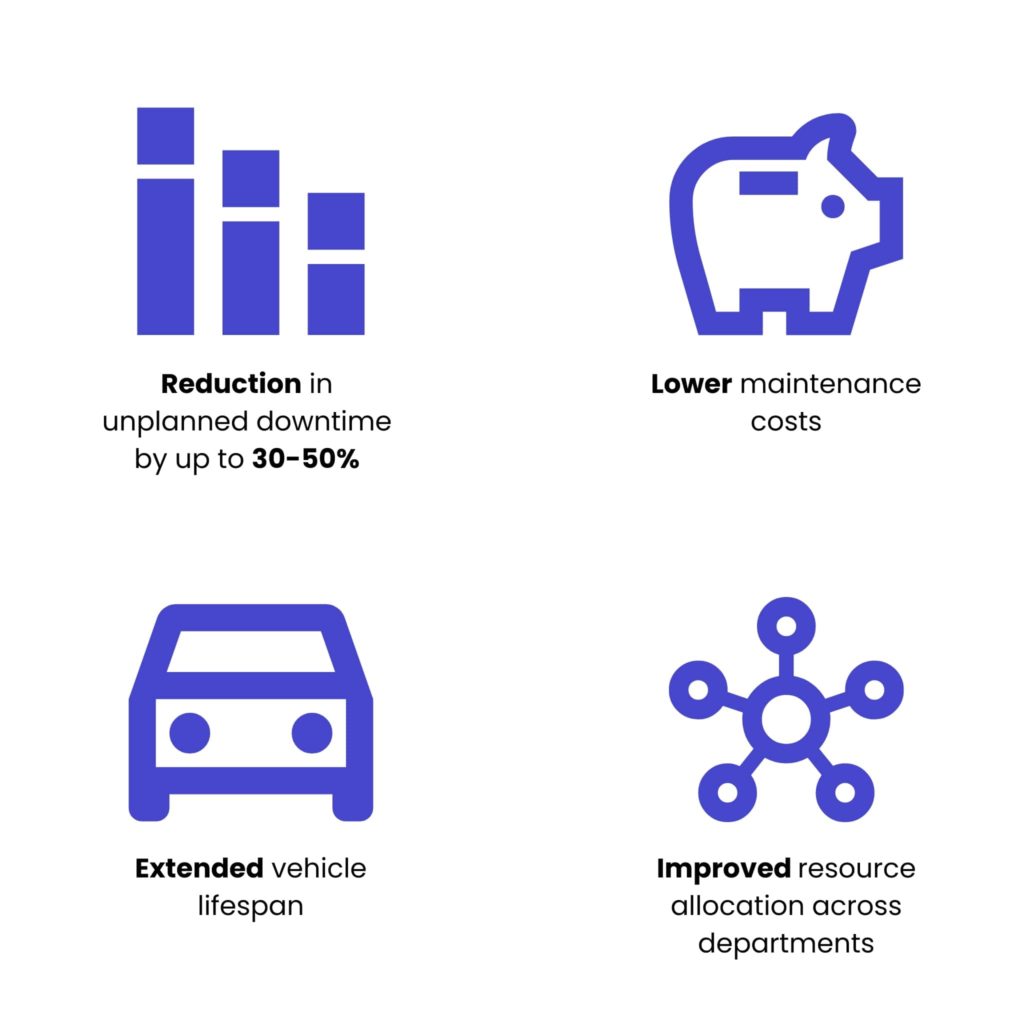

For enterprise-scale mobility businesses, the financial benefits of predictive maintenance are both immediate and long-term.

Automated forecasting results in measurable improvements across key performance indicators:

- Reduction in unplanned downtime by up to 30-50%

- Lower maintenance costs through more precise scheduling and early intervention

- Extended vehicle lifespan due to optimal usage and care

- Improved resource allocation across departments

Predictive models can also flag underperforming assets or usage anomalies, helping fleet managers make better decisions regarding replacements, redeployments, or redesigns.

In short, what starts as a maintenance strategy quickly becomes a true business advantage, especially when integrated with sales forecasts to refine budgets and prepare for potential challenges.

Why now? And, why Spyrosoft?

The technology is ready, your data is already flowing…

What’s often missing is a clear strategy, proper system architecture, and the ability to integrate it all into something actionable within your business systems.

That’s where our expertise comes in. At Spyrosoft, we bring:

- Deep experience in building AI-powered, telemetry-driven solutions.

- A track record of supporting global clients across automotive, logistics, and enterprise software sectors.

- A consultative, cross-disciplinary approach, ideal for complex, multi-departmental organisations.

We collaboarate with you to design intelligent predictive maintenance systems, tailored to your architecture, business goals, and operational landscape. Let’s turn your data into decisions – with the right approach, predictive maintenance can become a catalyst for smarter vehicles, empowered teams, and sustainable growth.

Want to make the shift from fixing to foreseeing? Let’s talk about how Spyrosoft can help you develop your predictive maintenance strategy.

FAQ

Preventive maintenance follows fixed schedules; predictive maintenance uses data and AI to intervene only when needed, which is more efficient and cost-effective.

You can start with what you already have, e.g. historical maintenance logs, failure reports, sensor data, and operational records. These become the foundation for training ML models.

Forecast accuracy improves over time as the model ingests more data and learns from outcomes, especially when feedback loops are in place.

Yes. Automated forecasting systems are designed to handle complex, large-scale environments and can be customised to fit different asset types and conditions.

Not necessarily. Spyrosoft provides end-to-end support – from model development to integration – so your team don’t need to be AI experts to benefit.

About the author

Contact us

![[hero] client loyalty and predictive maintenance](https://spyro-soft.com/wp-content/uploads/2025/04/hero-client-loyalty-and-predictive-maintenance-300x200.jpg)