How AI solves aviation’s maintenance capacity crunch

In our previous article, we unpacked the growing challenges facing aviation maintenance. If you haven’t seen it yet, dive into why traditional strategies are no longer enough. Now, let’s focus on the solution side. In this article, we’ll explore how predictive maintenance actually works, where the industry stands today, and what it takes to implement these systems in practice.

Predictive maintenance maturity spectrum

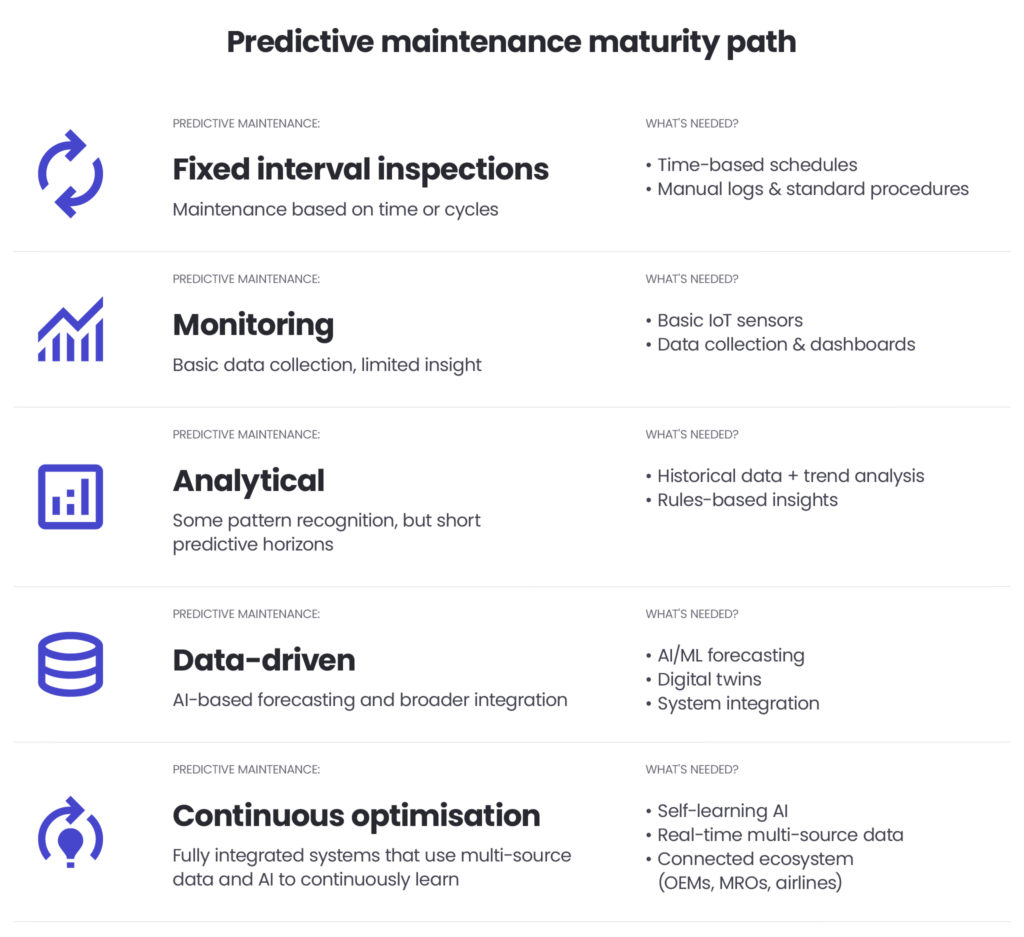

Predictive maintenance isn’t all-or-nothing or a binary switch. Adoption across aviation varies widely. Maturity can be viewed on a five-stage spectrum:

- Fixed interval inspections (maintenance based on time or cycles)

- Monitoring (basic data collection, limited insight)

- Analytical (some pattern recognition and trend analysis, but short predictive horizons)

- Data-driven (AI-based forecasting delivering actionable insights, broader integration)

- Continuous optimisation (fully integrated systems that use real-time, multi-source data and AI to continuously learn and adapt maintenance decisions)

As organisations progress across these stages, not only do efficiency and cost benefits grow, but so does operational safety. The biggest gains await those that move toward levels 4 and 5.

AI & digital twins in action

Major aviation players are already using AI and digital twins to rewrite the rules of engine maintenance. What’s emerging isn’t just better data, but rather a connected ecosystem where insights from sensors, operations, and service histories flow into a single source of truth that drives smarter decisions.

Across the industry, we’re seeing powerful examples:

- GE Aerospace uses AI-powered digital twins across its engine fleet to model individual engine behaviour and forecast repair scope and part requirements before the engine arrives at the shop. Their predictive models provide recommendations down to the part number level, enabling precise logistics and minimising turnaround time.

- Collins Aerospace’s (RTX) Ascentia platform, used by Japan Airlines, combines predictive analytics with operational data to help reduce unscheduled maintenance costs by up to 20%. It’s an example of how embedding intelligence into daily operations can deliver immediate savings.

- Rolls-Royce’s Blue Data Thread creates two-way flow of insights between OEMs, airline operators, and MRO providers. It enables real-time updates on part usage, component behaviour, and upcoming deadlines, helping to avoid unplanned failures and supporting better scheduling. It also helps improve sustainability metrics by reducing unnecessary part replacement and optimising component life.

Maximising uptime – the core business metric

In aviation, uptime is more than a performance metric.

Every grounded aircraft means lost revenue, cascading schedule disruptions, and a dent in passenger trust. Thanks to predictive maintenance, aircraft are kept in service longer, with fewer surprises.

By spotting potential issues before they happen, AI-powered systems help extend Mean Time Between Removals (MTBR) and drastically reduce these costly Aircraft on Ground (AOG) situations.

We partner with airlines, OEMs, and MROs to translate engine data into actionable uptime strategies

Let's talkAt Spyrosoft, we create predictive platforms that help you:

- See what’s happening across your entire fleet in real time.

- Plan maintenance smarter with data-driven forecasts.

- Boost on-time performance and keep your fleet ready to go.

- Let engineers fix problems early instead of reacting to failures.

In a high-pressure environment with limited capacity, uptime is the true competitive edge. With predictive maintenance (done right), that advantage becomes sustainable and scalable.

Data & integration challenges: What’s holding the industry back?

While the vision is clear, the path to implementation isn’t always smooth. Most aviation players still deal with fragmented systems, siloed data, and legacy IT architectures.

Valuable data is often locked away in disconnected sources, scattered across engine logs, OEM databases, maintenance records, and airline ERP systems. Even when the data is accessible, it’s not always clean, consistent, or easy to integrate.

To make predictive maintenance work in practice, organisations need:

- Clean, structured engine sensor data.

- Cross-platform data integration.

- Training and aligning maintenance crews with new predictive workflows.

- Collaboration between IT, engineering, supply chain, overhaul shops, and airlines.

- Managing data sovereignty, keeping sensitive information protected.

And that’s where the right strategic partner can make a difference.

Strategic ROI: Turning tech into business value

Predictive maintenance is more than an operational improvement. For airlines, engine OEMs, and MRO providers alike, the value goes far beyond fewer breakdowns. The entire ecosystem becomes leaner, faster, and more resilient.

Let’s talk outcomes:

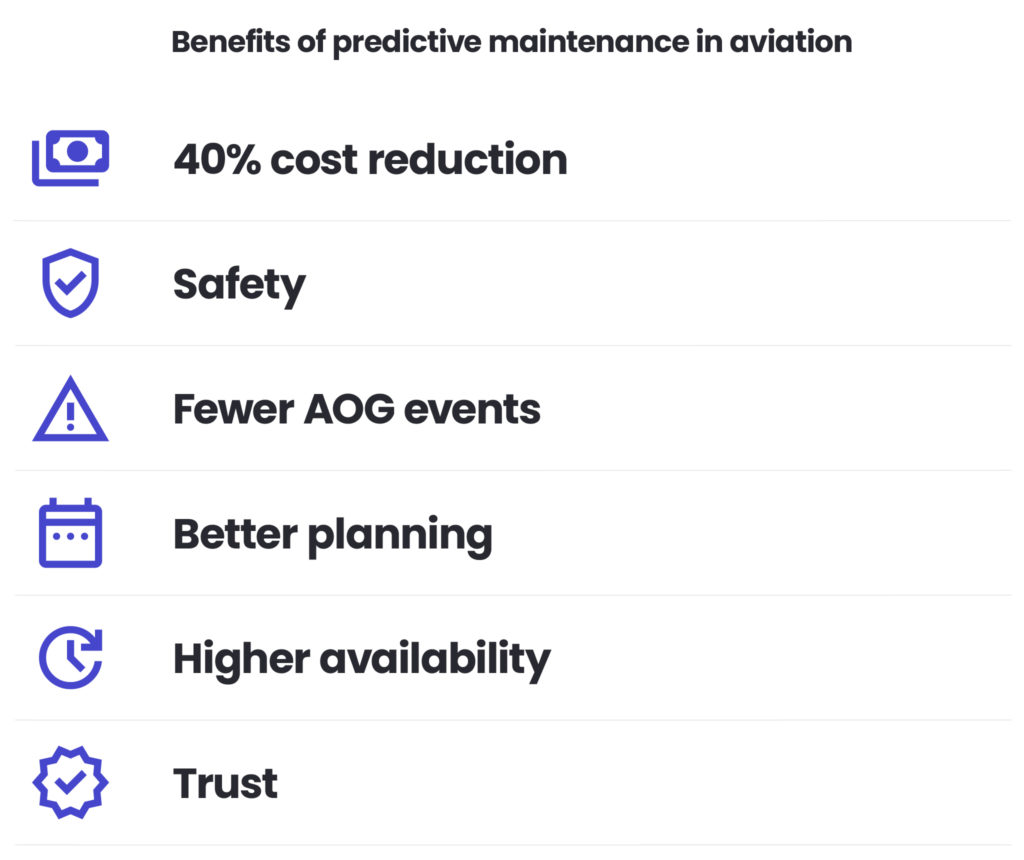

- Up to 40% reduction in maintenance costs by minimising unnecessary part replacements and extending component life.

- Improved safety by reducing the risk of premature part failure.

- Fewer AOG events, as issues are addressed before they cause disruption.

- Improved MTBR (Mean Time Between Removals), supporting longer service intervals and better engine utilisation.

- Smarter parts planning, reducing waste and supply chain friction.

- Enhanced customer experience thanks to fewer delays and greater schedule reliability.

Ultimately, in an industry defined by tight margins and rising demand, predictive maintenance helps airlines fly more passengers with fewer disruptions. It lets airlines scale with confidence, and deliver reliability that passengers notice.

Why digital integration partners matter

To bridge the gap between insight and action, aviation players need solution architects who understand both aviation operations and intelligent digital systems.

Spyrosoft helps organisations:

- Collect and standardise data from multiple systems in a secure way.

- Build predictive analytics platforms tailored to engine maintenance.

- Integrate AI into daily maintenance planning.

- Scale predictive capabilities across global fleets.

We act as a trusted partner and the architect of customised solutions. We help our partners bridge the technical and operational gaps – and integrate secure, intelligent predictive systems into the heart of engine MRO strategies. Every minute matters in aviation, and with the right data, you’re one step ahead.

Read part 1: Why predictive maintenance is no longer optional in aviation?

Go to the articleConclusion

Predictive maintenance used to be seen as an emerging innovation. Today, it’s quickly becoming the industry standard. This approach is a natural next step that builds on existing procedures, simplifying maintenance while simultaneously enhancing safety.

Success in aviation won’t come from simply having the latest technology. Instead, it will belong to those organisations that quickly adopt and effectively use digital tools to manage maintenance in smarter, more integrated ways.

By turning engine data into uptime with predictive AI, they’ll gain stronger customer confidence, greater fleet availability, and smarter use of capital and labour.

With the right digital partners, those capabilities don’t have to remain out of reach, and even the most grounded challenges can become gateways to transformation.

About the author

Contact us

![[hero] predictive engines 1](https://spyro-soft.com/wp-content/uploads/2025/06/hero-predictive-engines-1-300x169.jpeg)

![[hero] predictive engines 2](https://spyro-soft.com/wp-content/uploads/2025/06/hero-predictive-engines-2-300x160.jpeg)