Why predictive maintenance is no longer optional in aviation?

The aviation industry is hitting turbulence like never before – not in the skies, but on the ground. New aircraft deliveries are stuck in production backlogs, engine overhaul shops are overbooked months in advance, and global air traffic is surging. Aircraft (and engines) are flying more frequently to meet demand – accumulating flight cycles faster and hitting maintenance thresholds sooner.

The result? A storm of mounting maintenance pressure across the fleet, scarce serviceable parts, and skilled crews stretched to the limit.

Why aviation maintenance needs a data revolution

In 2024 alone, global MRO (Maintenance, Repair and Overhaul) spend reached $114 billion – a 7.2% increase over pre-pandemic highs in 2019 – and the climb isn’t slowing.

The critical question the industry now faces is no longer technical. It’s existential in nature: How do we keep planes flying in the air when everything on the ground is running out of room, resources, and time?

A growing number of aviation leaders are finding the answer to this in data. Predictive maintenance and health monitoring – powered by data science, digital twins, and real-time engine data – is becoming a smarter, faster, and more scalable way to manage aviation’s most urgent operational challenges, with the potential to cut maintenance costs by up to 40%.

By harnessing data, predictive maintenance enhances both security and efficiency, identifying issues before they become critical to ensure safer flights while optimising maintenance workflows.

At Spyrosoft, we’ve seen how smartly integrated real-time analytics and AI can provide aviation decision-makers with the insights they need to act faster, reduce delays, and manage fleets more efficiently. Our teams combine deep expertise in data science and digital engineering to build tailored platforms that transform raw engine data into powerful insights.

The MRO capacity crunch

As OEMs struggle with high demand, production delays and delivery backlogs, airlines are relying more heavily on older aircraft still within service limits to meet operational needs.

While that strategy makes sense financially, it also means aircraft are flying more often and accumulating cycles faster, accelerating the need for maintenance across the fleet. The ripple effect?

Backlogged MRO facilities, longer turnaround times, and tough decisions around fleet availability. Grounded aircraft, delayed routes, and rising operational costs are becoming everyday realities.

Some OEMs are now exploring AI and digital tools to accelerate production and ease delivery bottlenecks, but relief is still a long way off.

Put simply: the system is overloaded, and the maintenance backlog is pushing airlines to rethink how they maintain operational readiness at scale.

The parts & people bottleneck

What’s really slowing everything down?

There are two major forces:

- Skilled labour shortages – many shops struggle to hire and retain qualified technicians fast enough to meet rising demand. Even when crews are available, they may not be in the right place at the right time (and sending them off-site for inspections or repairs adds further delay). Also, many experienced workers left during the pandemic, and training pipelines haven’t caught up.

- Parts scarcity and supply chain strain – serviceable parts (such as life-limited components or overhauled modules) are increasingly hard to source exactly when and where they’re needed. According to industry surveys, 75% of MRO professionals report longer engine service times, largely due to parts availability issues.

Together, these two shortages amplify one another. With fewer hands to do the work and fewer parts to complete the job, every unplanned event becomes a high-stakes disruption.

Why fixed interval strategies no longer work

For decades, aviation maintenance largely relied on fixed interval schedules rather than real-time condition monitoring. While this planned approach ensured reliability, it can lead to unnecessary maintenance and missed early warning signs.

The old model is becoming increasingly costly and inefficient.

Why? Because in aviation, where schedules run tight and downtime costs soar, fixed interval maintenance is simply too disruptive and too expensive.

The results are striking:

- Studies show that unplanned maintenance can cost 3-4x more than scheduled interventions.

- Emergency repairs trigger higher labour costs, premium shipping for parts, and rush logistics.

- AOG (Aircraft on Ground) events wreak havoc on scheduling and passenger experience.

In an industry as tightly choreographed as aviation, there’s no room (or budget) left for surprises.

Predictive maintenance, explained

The skies are demanding something smarter – and that’s where predictive maintenance changes the game.

Imagine knowing exactly when your engine will need servicing, tailored to its unique condition and usage, weeks before a warning light appears. Imagine knowing exactly when your engine will need servicing, tailored to its unique condition and usage, weeks before a warning light appears.

That’s exactly the promise of predictive maintenance, or condition based maintenance (CBM).

How it works

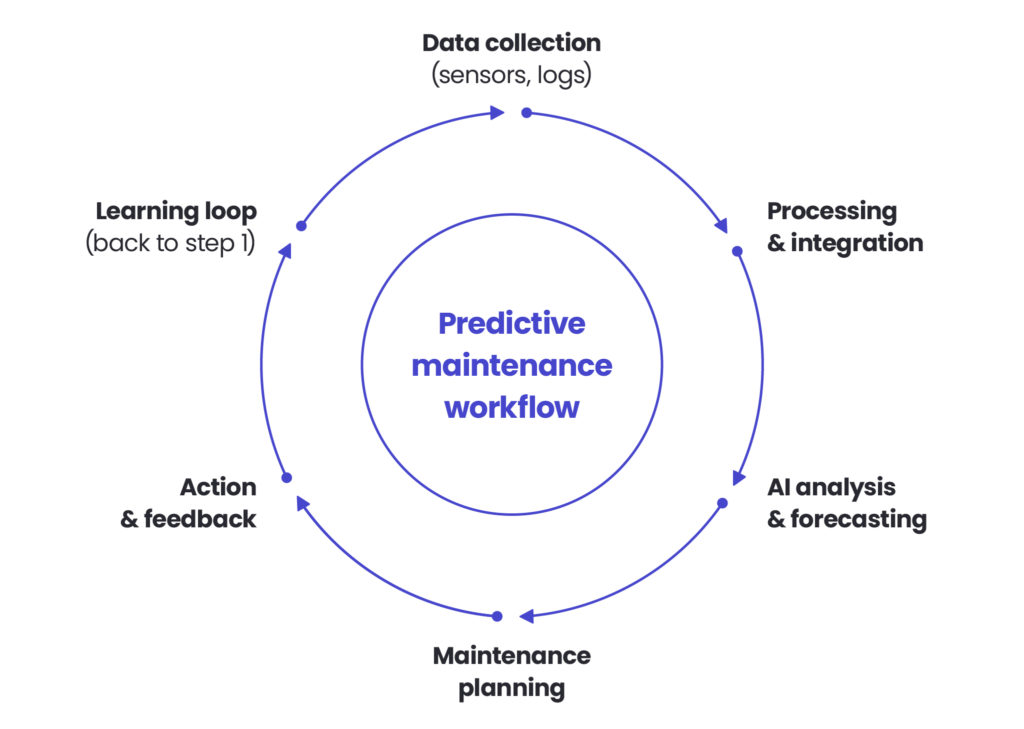

- Advanced algorithms process vast amounts of historical and operational data. This includes prior nonconformances, engine load, usage patterns, and detect possible failure models and wear accumulation.

- Live sensor data captures current performance and environmental conditions during flight.

- These insights generate targeted maintenance recommendations, prioritising the right work at the right time.

- Once actions are taken, the system gathers feedback and re-learns, improving its models continuously in a learning loop.

By analysing a mix of historical trends, production data, lifetime condition, environmental data, fleet-wide field experience (including Weibull analyses), and real-time engine sensor streams, AI-powered systems forecast wear, detect anomalies, and predict component issues before they ground the aircraft. Instead of waiting for components to fail, these systems model how, when, and why they will.

This predictive maintenance workflow isn’t linear: it’s dynamic and intelligent. Each completed cycle feeds back into the next, creating a smarter, faster, and more precise system with every iteration.

Proactive safety through prediction

In aviation, safety is non-negotiable. Predictive maintenance enhances it by identifying potential failures before they happen – preventing delays and protecting lives. By spotting early signs of wear or malfunction, AI-driven systems enable timely interventions that reduce in-flight incidents and unscheduled removals. In many cases, these systems catch what traditional schedules miss.

Aviation safety is process-based. It relies on strict procedures and routine inspections – all to ensure reliability even without real-time insights into component health.

Predictive maintenance doesn’t replace these checks, but enhances them. Adding an intelligent layer to existing procedures brings greater clarity, boosts efficiency, and increases confidence in every maintenance decision.

At Spyrosoft, every time we helped clients move from fixed interval strategies to predictive control, they’ve experienced faster planning cycles, improved safety, and more efficient planning of resources.

By creating scalable data infrastructures, intuitive dashboards, and aviation-grade AI models, we empower aviation teams to plan better, act earlier, and fly safer.

Read part 2: How AI solves aviation’s maintenance capacity crunch

Go to the articleConclusion

In a system pushed to the edge, predictive maintenance offers a smarter, safer, and more sustainable path forward.

By shifting from reactive fixes to proactive insights, it helps airlines, OEMs, and MROs keep fleets flying, reduce unexpected costs, and make better use of limited capacity.

To make it a reality, you need the right tools, technologies, data, and strategic mindset.

In the next article, we’ll dive into the practical side: what it takes to get started, how leading organisations are already doing it, and how you can begin implementing predictive maintenance in your own operations.

Ready to take the first step? Let’s explore what’s possible.

About the author

Contact us

![[hero] predictive engines 2](https://spyro-soft.com/wp-content/uploads/2025/06/hero-predictive-engines-2-300x160.jpeg)

![[hero] predictive engines 1](https://spyro-soft.com/wp-content/uploads/2025/06/hero-predictive-engines-1-300x169.jpeg)