Digital twin software

Enhance operator’s comfort, reduce operational expenses, and boost site safety with a virtual model of the machinery and its environment that ensures immediate two-way communication, work progress tracking or running simulation scenarios.

The modern challenge

Today’s worksites, especially in the realms of heavy machinery and agriculture, are bustling hubs of activity. The rapid pace and high stakes mean that errors can be costly, accidents more frequent, and even your best employees can feel the strain.

As technology advances, the need for precise navigation and steering becomes paramount.

How can industry leaders keep up?

Przemysław Krzywania

HMI Director

What is digital twin software?

Imagine having your machinery’s real-time, virtual counterpart integrated right into an onboard interface or in the construction manager’s tablet. This isn’t just a digital replica; it’s a mirror reflecting every operational detail of your equipment.

What you can expect from the digital twin software

Operator support & comfort

- Precision in daily tasks with live views from every angle

- Directions and tasks sent to the machine’s HMI

- Full or partial remote machine control

Lower operation costs

- Cost savings from reduced fuel consumption, wear monitoring, and more

- Lower entry level and streamlined training process with VR capabilities

- Well-considered operations with simulations done beforehand in VR

Site safety

- Software-machine movement limitations for fewer errors and accidents

- On- and off-site monitoring

- Real-time devices status updates

R&D initiative

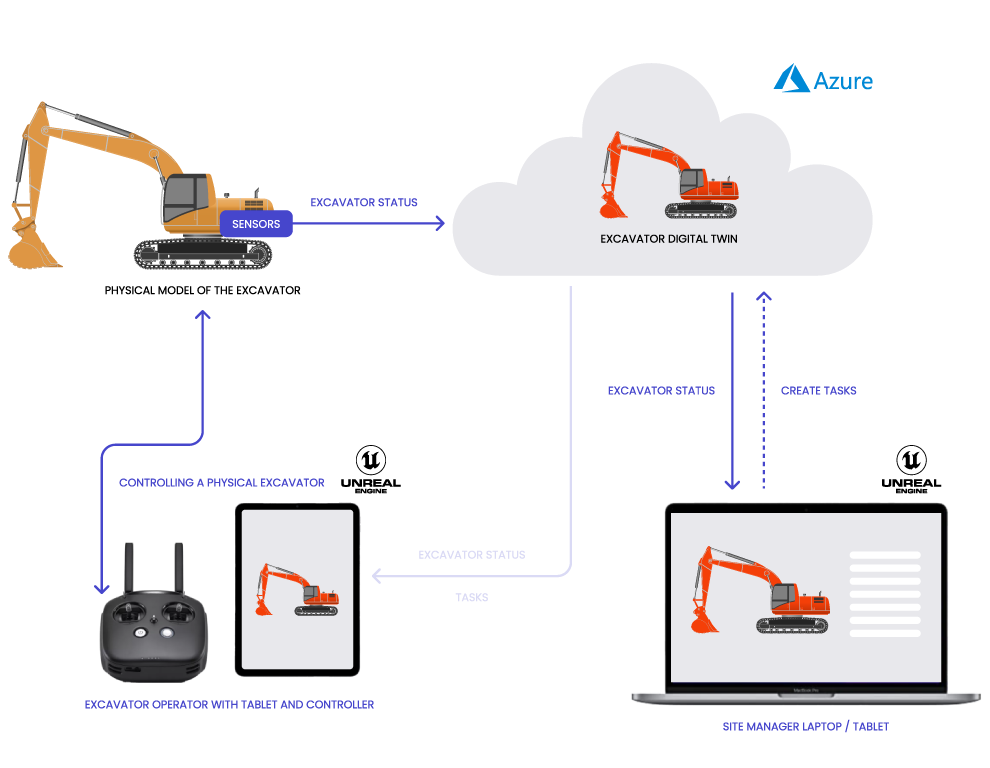

A digital twin of an excavator developed in Unreal Engine 5

DigiTwin aims to support the machine operator via a tablet inside the cockpit, increase safety and reduce costs with a supervisor’s application for remote site monitoring.

Our HMI software provides smooth motion reproduction without delays or micro-/high-frequency movements. During the initiative development, we overcame significant device obstacles, and the software is now optimised for onboard hardware and reduced data transfer. The concept and its features can be transferred to other heavy or agricultural machinery.

DigiTwin features

IoT-enabled sensors for real-time inputs

A detailed 3D digital twin capturing sensor data, showing status, machine position and live movement

Intuitive HMI accessible via onboard interfaces, tablets, or PCs

Two-way communication between the device and the application

Secure data storage in the cloud or on the ROS controller

AR/VR headset combability for immersive experiences

Clients say about us

Partnerships

contact us