Innovation Lab: Azure IoT Hub and HoloLens

If you’ve ever worked in any type of industrial environment, you’ll know it poses a unique set of challenges. One of these is the accessibility of the plant machines and the fact that they are built to last 15 – 20 years. This makes any repairs and maintenance almost impossible, and even a simple assessment of the status of the device can be demanding. HoloLens is the latest product from Microsoft aimed at completing such tasks with ease.

Connecting Azure IoT hub with HoloLens

We used it in one of our latest projects where we prepared a demo with a hardware part in the field – a small computer where we will connect a temperature sensor and an air quality sensor. These are connected to the internet via Wi-Fi, with this connection being used to link the computer with the Azure IoT hub to send the data from the sensors.

Data visualisation with HoloLens

On the service end, we process the data and then present it to the end user. This presentation is done by displaying the data using HoloLens, a holographic eyewear from Microsoft. This will allow the user to access the visualised data as they approach a machine connected to the Hub. This will be available thanks to the QR codes on the machine. The eyewear could then check the data from the machine via the IoT Hub and a suitable application.

One of the use cases could be using this setup for machines that are in difficult-to-get locations inside a plant. Watch the case study video from Microsoft to learn more about using HoloLens in an industrial setting here.

Product testing with Digital Twin

We started working on this project a few months ago, successfully getting our computers to communicate with the Hub, and completed it in February 2022.

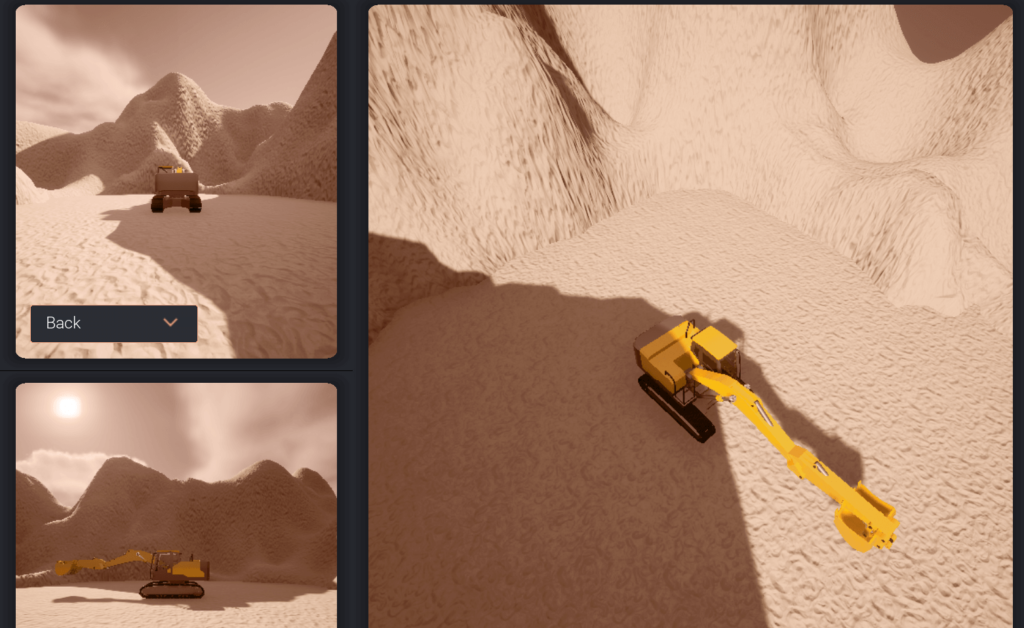

We worked on optimising the software and making it even more reliable. We then used machine simulations from Microsoft, where you can set up Digital Twins for your devices. This way, we are able to better test our product and deliver valuable functionality for our future clients.

By using the Digital Twin service, our customers will be able to set up virtual versions of their machines or devices in the cloud and experiment with this network before they introduce any changes to the actual, real-life machines in the plants.

About the author