The role of rapid prototyping in SDV

In today’s automotive industry, speed is of the essence. With competition from outside of the old continent in delivering new functionalities, the need to innovate swiftly and efficiently has never been greater.

Traditional development cycles, particularly in markets such as Germany, are under strain as more agile players bring their innovations to market faster. This is where rapid prototyping in Software-Defined Vehicles (SDVs) becomes a game-changer. Container-based prototyping environments allow for faster iterations and more efficient software updates, greatly enhancing development. As a result, work is sped up, no need to wait for dedicated hardware, and software can be created in an environment that is easy to migrate to a dedicated platform.

The shift towards software-defined vehicles

Historically, the automotive sector has relied heavily on a hardware-driven approach. Development cycles are long, with a focus on ensuring reliability, precision, and safety. However, the rise of SDVs marks a significant shift in this paradigm. SDVs are not bound by the limitations of traditional hardware; instead, they are defined by the software that runs on them. This shift allows manufacturers to introduce new features and functionalities dynamically through software updates, even after the vehicle has left the factory.

For OEMs (Original Equipment Manufacturers) and automotive developers, the message is clear: it’s no longer enough to focus solely on hardware. The future is in software, and the key to staying competitive is being able to rapidly prototype and iterate on these software features. Automotive developers face challenges in acquiring adequate hardware for real-time performance applications, such as autonomous driving and advanced driver-assistance systems. Cloud-based solutions enable them to prototype and validate their software efficiently, bridging the gap between virtual testing and real vehicle testing environments. This is where software engineering becomes crucial, as it allows teams to efficiently iterate on designs and reduce time and costs associated with product development.

Check out our automotive services

Learn moreRapid prototyping in SDV: a competitive advantage

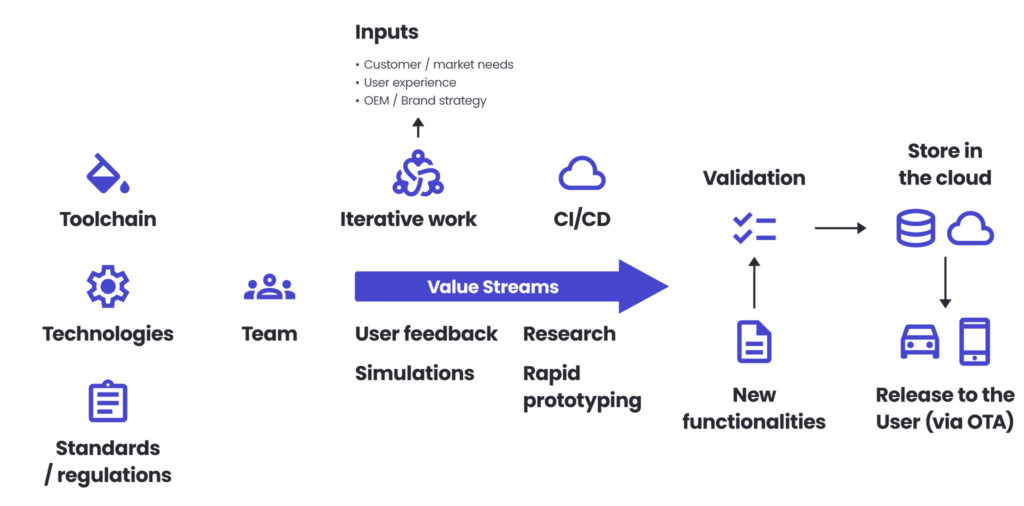

Rapid prototyping allows manufacturers to shorten development cycles and accelerate time-to-market. By adopting iterative approaches, automating processes (through CI/CD tools), and minimising test loops, companies can significantly reduce the time required for both hardware and software integration. Creating software simulations (instead of testing on hardware or vehicles) allows for faster closing verification and covers more possible edge scenarios. The development and automation of processes for creating circuit boards in the 1970s and 1980s played a crucial role in this evolution. In fact, this approach can decrease the overall development time by up to 40-50%. This is particularly beneficial for developing and testing autonomous driving features, where rapid prototyping enables the swift validation of complex systems and real-time computing requirements.

In this context, the uprising approach stands in stark contrast to the more traditional model. Where Western-European manufacturers are known for their perfectionism and long, sequential development cycles, Tesla has embraced agility. The company is able to bring products to market faster, albeit with the understanding that they may require further refinement after launch. This is enabled by the extensive use of Over-The-Air (OTA) updates, a hallmark of SDVs. The ability to update and improve vehicles post-production allows Tesla to adapt quickly to market changes and consumer demands.

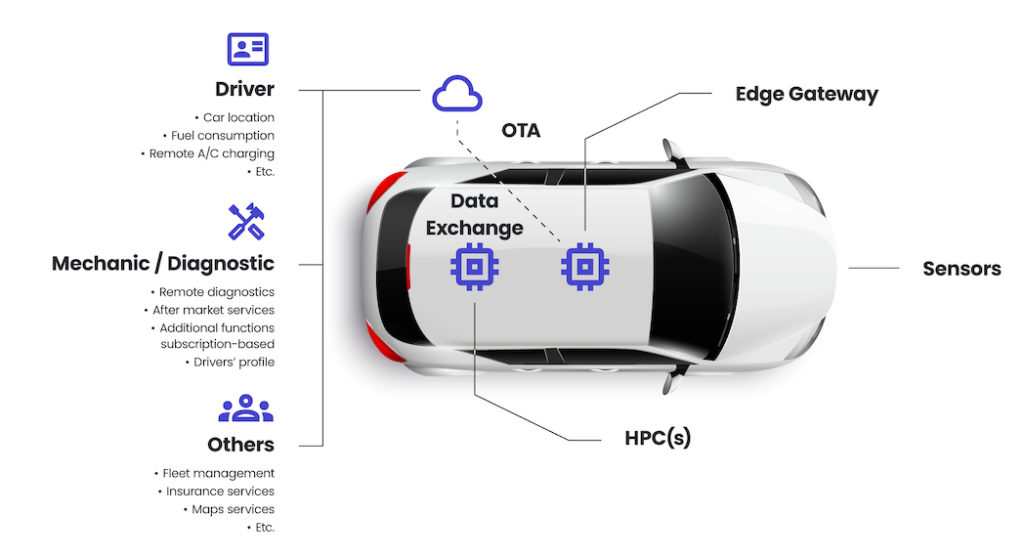

Such an approach leads to the development of new technologies, such as connecting cars to the cloud, and creates new and interesting use cases for drivers and carmakers. For example, apps that enable drivers to see the location of their cars and access data such as fuel consumption, estimated range, and the current location of the vehicle. Additionally, car manufacturers can collect data from car users for remote diagnostics, fleet management, and car owners’ driving profiles. The possibilities are truly endless, creating a whole new experience for the drivers. One can already speculate about the subscription services that are about to appear in the automotive industry in the same way as in any software-defined industry.

Integrating advanced driver assistance systems into rapid prototyping

One concern often raised about rapid prototyping in the automotive industry is the question of safety, particularly functional safety. After all, vehicles must meet strict safety standards, and quick iteration processes could seem at odds with this requirement. However, it’s entirely possible to integrate functional safety within an iterative development framework.

By implementing CI/CD automation tools, automated test loops, and structured use of open-source components, manufacturers can maintain high safety standards while benefiting from the speed and flexibility of rapid prototyping. Additionally, introducing a “safety path” – a system that ensures essential safety functions are prioritised even in fast development environments – ensures that vehicles remain compliant with the necessary safety regulations.

Classic vehicle development lifecycle: is it a dead end?

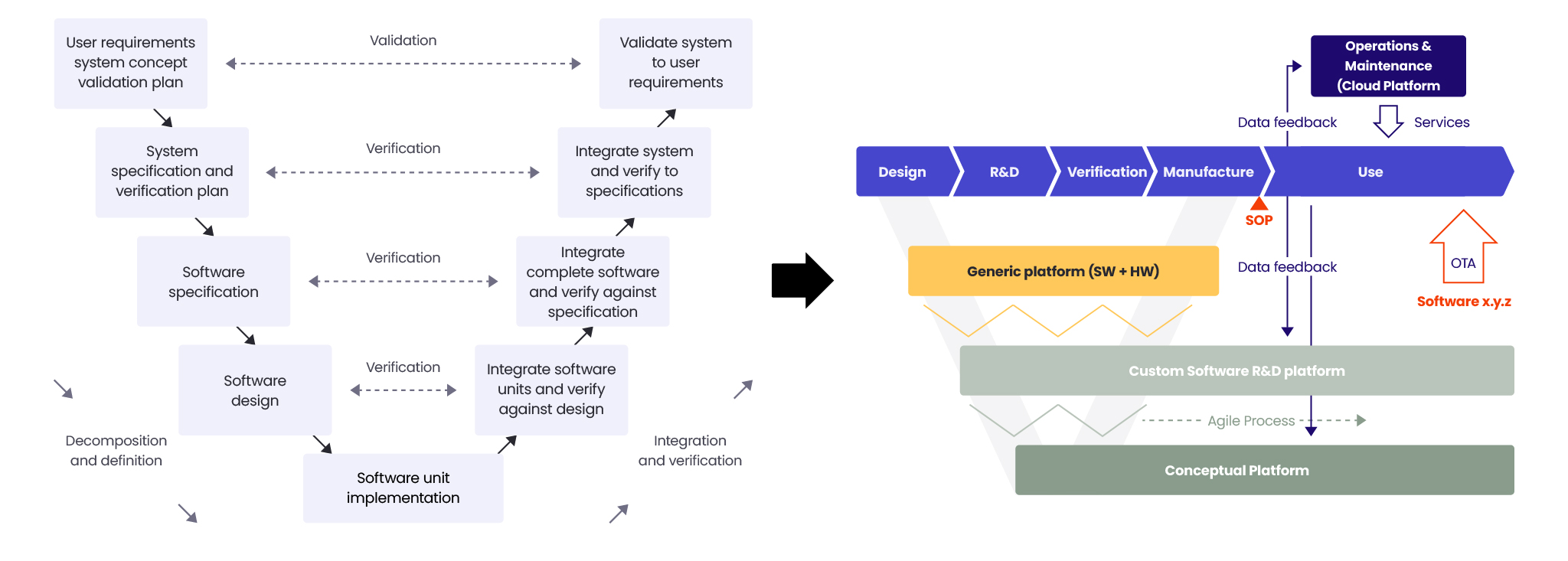

The traditional automotive model, exemplified by manufacturers, prioritises standardisation, waterfall approach and long-established technologies, such as Classic AUTOSAR, to minimise risks. While this method has historically ensured reliability and consumer safety, it is increasingly becoming a dead end in the face of faster, more flexible competitors. This is particularly evident in the development and integration of advanced driver assistance systems, where the complexity and need for cloud-based solutions and systems engineering are paramount.

European OEMs have been outsourcing significant work to Tier 1 suppliers for years, including software and hardware delivery and integration. This has led to change requests and contract negotiations, but it hasn’t changed much recently. Companies present in the automotive market for decades have a more conservative approach to releasing software, requiring thorough testing before giving a green light to release to end users. In this business sector, reliability is crucial, and car manufacturers are reluctant to treat drivers as beta testers. Additionally, they adhere to very conservative levels of regulation compliance and are unwilling to deliver a product that may be in any way non-compliant with current norms.

Increasingly popular electric vehicles mark their place on the modern automotive landscape, necessitating robust charging infrastructure and seamless user experiences. In this context, Tesla’s approach has revolutionised the industry with faster development cycles, frequent software updates, and a willingness to release products that are not entirely perfect from day one. While traditional European manufacturers focus on perfection through lengthy development cycles, the agility and speed in delivering innovations have allowed the relatively new manufacturer to dominate the market. This highlights the shift towards a software-driven approach, where flexibility and quick iteration take precedence.

What’s more, in software-defined vehicles (SDVs), there is less dependency on hardware, enabling more functions to be carried out with less. This leads to a so-called domain decentralisation. Traditionally, each function required its own dedicated ECU (Electronic Control Unit), meaning hardware was tightly coupled to specific tasks. Today, however, SDVs allow for more powerful ECUs to handle multiple functions, such as infotainment, ADAS (Advanced Driver Assistance Systems), and connectivity through HPC (High Performance Computing Platforms) tightly connected with Edge Gateway This consolidation of tasks not only streamlines the vehicle’s architecture but also exemplifies the shift towards a more software-centric approach in automotive development.

Why rapid prototyping in SDV is the future

The shift towards SDVs is no longer just a trend; it’s becoming the new standard. More and more vehicles on the market today, from manufacturers such as Tesla, Rivian, and Lucid Motors, offer OTA updates and software-defined functionalities, creating a connected car environment through an open community. For traditional automotive companies, the message is clear: invest in SDV development now, or risk being left behind.

For OEMs and automotive manufacturers, rapid prototyping is not just a tool – it’s a necessity. The ability to quickly iterate and innovate in software development is what will separate the winners from the losers in the SDV race. While traditional approaches to automotive development have their merits, they are increasingly incompatible with the demands of modern consumers and the speed of technological change. Those who embrace rapid prototyping will find themselves well-positioned to thrive in the era of SDV applications.

Spyrosoft’s expertise in SDV delivery

At Spyrosoft, we have extensive experience in delivering cutting-edge software solutions for the automotive industry, including the implementation of software-defined vehicles. Our team of experts has worked alongside global OEMs and Tier 1 suppliers, successfully navigating the complexities of rapid prototyping, cloud-based development environments, and integrating functional safety into agile workflows. With our deep industry knowledge and technical expertise, we are well-positioned to guide manufacturers through the transition to SDV, ensuring seamless integration, rapid innovation, and long-term success.

If you’re ready to embrace the future of automotive development, we invite you to explore how Spyrosoft can support your journey towards a software-defined vehicle.

About the author

Contact us