HMI technology in the fields: What opportunities it brings for the agritech sector

Agriculture is evolving rapidly, especially when it comes to technological advancements. This sector now benefits from modern machines that automate a lot of work and solutions such as IoT and AI that make farming work far more effective. One of the trends that has come to the fore recently is HMI technology. How can human-machine interfaces improve the way your agritech company operates?

When agriculture and technological innovation meet, the results are just spectacular. The latest tech advancements revolutionise traditional farming practices – from autonomous agricultural machinery to artificial intelligence and sustainable solutions, the agriculture sector is now enhancing efficiency and productivity but is also becoming more sustainable. While there are several fascinating trends in agritech services, there is one that deserves special attention, namely – automation in agriculture, especially through HMI – human-machine interfaces.

In this article, we will show you how your agritech company can implement and benefit from the HMI technology. But let’s start from the beginning.

Automation in agriculture – how the latest technology advancements make the work more effective

There are several interesting technology trends to watch in this sector in 2023 and beyond. For instance, the use of drones is becoming increasingly popular these days in agriculture. Drones can be used to plant trees, monitor crops, spray herbicides, or for fruit-picking purposes. According to ExplodingTopics.com, the search results for “agricultural drone” are continually going up (119% in the last 5 years), and this sector is predicted to grow at a +20% CAGR rate.

For example, Precision AI, a Canadian agritech startup, developed an advanced drone-based computer vision technology for guided weed targeting in row crop farming. Thanks to this technology, the drones can spray only the problem areas and not waste herbicides spraying on bare ground or healthy crops. Precision AI estimates their technology can help save farmers up to $52 per acre per growing season.

Another interesting trend is related to vertical farms. Their popularity has been growing lately, primarily due to the fact they can provide fresh produce all year round. Back in 2021, the value of the vertical farming market was estimated at $3.1 billion. It is predicted that it will grow to a huge $9.7 billion worldwide by 2026, according to the New York Times.

Vertical farms frequently integrate automation and robotics for tasks such as planting, harvesting, and monitoring crop health. This reduces the need for manual labour, but also increases efficiency, and ensures consistent care for the crops. Automated systems are responsible for watering, lighting, and fertilising, but they are also used to plant seeds. As a result, everything is accelerated and more effective.

In 2023, there are many farms operating this way. One of them is Plenty – an agricultural producer located in San Francisco. Their indoor vertical farms are filled with robots and automated machines taking care of almost every single element of the farming process.

Speaking of automation in agriculture, there is one more trend that all agritech companies should be keenly interested in – human-machine interfaces. How can they make your agritech services better?

What is a human-machine interface (HMI) solution?

In general, HMI is a set of software and hardware solutions that allow human operators to monitor and control the way machines do their jobs. In the agritech sector, HMIs enable farmers and machine operators to interact with and control agricultural machinery and systems.

Many of the latest agricultural machines and devices (like tractors, harvesters, and other farming equipment) come with built-in touchscreen interfaces and data visualisation systems. These touchscreens are the perfect examples of HMIs. Through those systems, farmers can easily interact with and steer various functions and settings of a given machine. Additionally, these interfaces often provide real-time data on all the relevant factors and parameters, such as:

• fuel levels,

• soil conditions,

• yield monitoring,

• the machine’s location and the percentage of work done.

What’s important is that when it comes to agritech services, HMIs are not stand-alone solutions. They must be integrated with the machine itself and have access to relevant data points. Therefore, HMIs are usually part of precision farming equipment, automated machinery, and data monitoring systems.

Obviously, not every farming machine is equipped with an HMI system by default. Such features are usually available in the newest models and are frequently charged extra. Plus, there is a whole list of machines and devices that are not offered with HMIs, but they could definitely use them.

This is where our role begins. If you’re in a situation like this and would like to implement an HMI system in your farming equipment, read on, as this is possible even if your machines came to you without such a system. But before we get to this question, let’s have a look at the benefits of implementing HMI in an agritech company.

How the agritech sector can benefit from HMI implementation

There is a whole list of benefits that stem from the fact that your farming business is equipped with HMI solutions, enabling almost full automation in agriculture. Let’s have a look at them:

Full or partial remote control over your machines and devices

With HMIs, your agricultural machinery gains the capability for autonomous or supported machine driving. Why is this significant? For example, imagine the convenience of remotely guiding your equipment via just a normal tablet. Autonomous features not only streamline operations but also help you with resource optimisation, allowing your machines and devices to do their jobs with minimal human intervention. The ability to remotely control and monitor your agricultural machines gives you more flexibility, enabling your farmers to manage multiple tasks simultaneously.

Machine operator’s comfort

With HMI systems, your machine operators can work in the cockpits equipped with tablets providing a real-time 3D view of every angle of the machine, its operations, and surroundings. HMI solutions offer operators the option not just to control the machine but also to get a comprehensive understanding of the working environment. Precise HMI navigation capabilities, coupled with the option to set up area boundaries for the machine (so that you don’t go into your neighbour’s field), ensure full work accuracy.

Monitoring the work progress

Thanks to HMIs, supervisors and managers can gain a bird’s-eye view of work progress through a desktop/mobile app, giving them real-time access to what’s going on. This feature provides them with complete insight into the machine’s status and condition. This way, tracking work progress becomes much easier, allowing for timely optimisations.

Simulations

HMI combined with a digital twin solution introduces the capability of running diverse simulations beforehand, allowing agritech companies to improve their farming strategies prior to implementing them in real-life conditions. You can use those simulations, e.g., to test different planting patterns or assess the impact of variable factors (e.g., the amount of herbicides used). Thanks to those simulations, making informed decisions and planning resources becomes much easier and quicker.

Cost reductions

Finally, with HMI-driven advancements, you can reduce the costs involved in running your agritech company. Automation in agriculture gives you access to reduced fuel consumption and wear monitoring. Moreover, the integration of software-driven machine movement limitations minimises potential errors and accidents, further reducing repair and maintenance costs. This way, HMI solutions not only enhance your operational efficiency but also mitigate risks and optimise resource usage.

Features that an agritech HMI should have to support the fieldwork

HMI is not strictly an agricultural solution. In fact, HMIs find applications in a lot of different market and industry sectors. Obviously, in each sector, HMIs look a bit different, as they need to be adjusted to the specific needs of a given industry.

When it comes to HMI automation in agriculture, there are at least six important features a good HMI system should offer:

- Intuitive UI: Farmers usually don’t have extensive experience with advanced IT systems. For them to operate HMIs, they must be easy to learn and intuitive to navigate. Moreover, in this niche, HMIs are usually used during fieldwork, so they should be comfortable to operate in different conditions and not distracting.

- Full mobile compatibility: Typically, there’s more than one person involved in fieldwork. With a web, mobile or desktop app, the company’s management can have real-time access to the latest information and data. To streamline data accessibility, HMIs should be mobile-friendly for real-time monitoring and control.

- Real-time data monitoring and analytics: In agriculture, conditions can literally change overnight. A good HMI system should provide real-time data on such elements as the weather (access to the latest weather forecasts is also very helpful), soil conditions and other relevant parameters. A built-in data analytics feature can also be very helpful and provide farmers with current insights on their crops and conditions so that they can make more informed decisions.

- Agriculture automation and remote control: Drones, irrigation systems, fertiliser spreaders and even GPS-guided tractors – all those machines and devices can be controlled remotely through HMI. This way, your farmers can make their work far more effective.

- Crop management: Advanced HMIs can support you in efficient crop management. The most advanced HMIs can assist you with tasks such as scheduling planting, pest control and the use of herbicides, irrigation, and fertilisation. Here, resource management (including water, fertilisers, and pesticides), by providing insights into usage and recommending optimal levels.

- Integration with IoT: Almost all of your farming tools and machines can be equipped with IoT sensors monitoring various conditions and parameters. There are IoT sensors enabling you to monitor soil quality, moisture levels, humidity, temperature, and other relevant parameters. If you want to make the most of this technology, you can integrate your IoT sensors with the HMI system.

Our HMI research & development initiative: DigiTwin case study

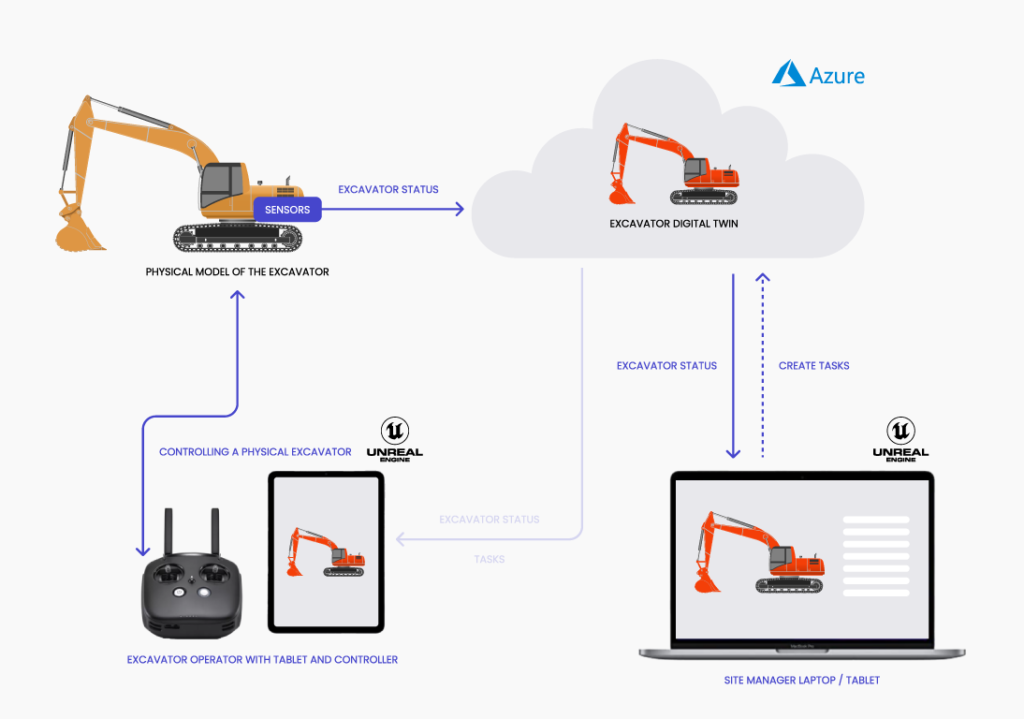

If you want to create an HMI system with a farming machine, such as a tractor or a harvester, you need to create its digital twin. In short, a digital twin is a virtual representation of a physical machine. To create a digital twin, we use IoT sensors and other devices to replicate the characteristics, behaviour and condition of the real machine. In other words, you get a virtual version of the machine, but you have real-time access to what’s going on with the real one.

With a digital twin, your HMI system has access to all the crucial parameters, and you can monitor and steer your machines more effectively, even if you are nowhere near the farm or the field.

Earlier this year, we developed such a product using Unreal Engine 5 technology. DigiTwin is an HMI research & development initiative, a digital echo of an excavator. The idea behind the project was to provide support for heavy or agricultural machinery as the concept could further be transferred to other devices. DigiTwin aims to support the machine operator via a tablet inside the cockpit, increase safety and reduce costs with a supervisor’s application for remote site monitoring.

Our HMI software provides smooth motion reproduction without delays or micro-/high-frequency movements. During the initiative development, we overcame significant device obstacles, and the software is now optimised for onboard hardware and reduced data transfer.

Take a look at the diagram showing the logistics of our project:

If you’d like to know more about this project, we invite you to have a look at this case study on our blog: HMI Dojo initiative: a digital twin development in Unreal Engine 5.

Summary

We hope this article helped you understand the full potential of agriculture automation with HMIs. With those systems, you can make your work easier, faster, and more effective. Moreover, you can plan farming work and manage crops in a streamlined manner thanks to easy access to the latest data and forecasts.

If you’d like to see how HMIs could work in your company, don’t hesitate to reach out. Start with our HMI development subpage and send us a short contact form (you will find it at the end of this subpage). We’ll take it from there!

About the author