Defect detection management – how to do it effectively

Defects are generally considered destructive at all stages of software development. However, no software is 100% free of them. Developing software free of bugs is impossible, but thanks to the defect detection management process (DMP), you can keep their number reduced to a minimum.

When a system produces a different result than the actual business requirement, i.e., when there is a deviation from the original idea, we can say that a defect has occurred in the software. These defects are responsible for unexpected or incorrect behaviour of the system. So, to properly manage digital (and physical, too) products, you need to know how to deal not only with the development of the product itself but also with potential defects. In turn, to effectively control and deal with defects, it is necessary to manage their life cycle properly. What do we mean by defect life cycle (frequently referred to as bug life cycle)?

What is a defect detection management life cycle?

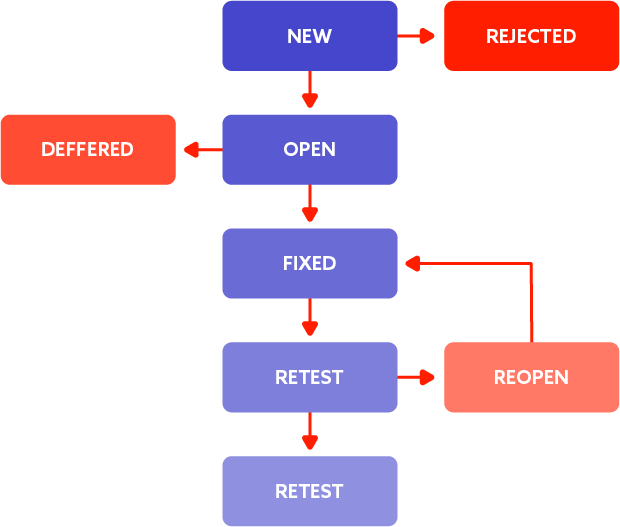

Once a defect is detected, it goes through various stages, commonly referred to as the defect life cycle. This cycle begins when the defect is detected or reported by the test team and ends when the development team eliminates the given glitch or problem. The number of states a defect goes through varies from project to project, but we can generally distinguish six primary stages:

Defect detection management step by step

The defect management process (DMP) is generally defined as identifying and resolving defects occurring in a product. Essentially, the entire process consists of several fundamental stages:

- Defect Prevention

- Deliverable Baseline

- Defect Discovery

- Defect Resolution

- Process Improvement

- Management Reporting

Below, you will find a brief description of each of the following stages.

STEP 1: DEFECT PREVENTION

Early elimination of defects is one of the best ways to reduce their effects. At an early stage, repairing or removing flaws also requires less time and money. At a later stage, defect repair can incur very high costs. At the same time, defect prevention, by fixing defects at an early stage, makes it possible to improve the quality of the entire software, prevent similar defects from appearing in the future, and enable the team to be more productive.

STEP 2: DELIVERABLE BASELINE

When a deliverable (application, system) or its component reaches its predefined milestone (a defined stage), it is referred to as a baseline. A predefined milestone usually defines what the project or software is supposed to achieve. If a predefined milestone is not achieved, it simply means that the project is not progressing as planned. That is a stimulus for project managers to launch corrective actions. Once the result is in line with the milestone, other elements and changes are controlled.

STEP 3: DEFECT DISCOVERY

The defect identification process allows a defect to be detected before it becomes costly to the entire project. A defect is considered when it has been formally reported to the development team and deemed valid.

STEP 4: DEFECT RESOLUTION

At this stage, the defect is resolved and corrected by developers. After the work is completed, programmers imply changes again to where the defect was originally identified.

STEP 5: PROCESS IMPROVEMENT

All identified faults are critical and affect the system. Even minor defects allow lessons to be learned, the process to be improved, and any future defects that may affect the system failure to be prevented. To improve the process, all project participants must look back, identify the source of the defect and then correct each detail.

STEP 6: MANAGEMENT REPORTING

The management board should be familiar with the stages of defect management in a project and its fixing. They must understand the entire defect management process. That will enable them to support the test manager. Therefore, the test manager should report the current situation to management so that they can get quick feedback from them.

Check out our AI/ML offerings!

Find out moreGoals of the Defect Detection Management Process

After wading through the theoretical issues, you may ask yourself, why implement this whole process? The primary goal is to prevent defects in the first place by finding them as quickly as possible and minimizing their impact. The defect detection management process is designed to ensure that defects are identified, managed, tracked, and, ultimately, corrected.

The main goal of defect detection management is to improve product quality by eliminating all defects from developed products for maximum customer satisfaction. But that’s not all. Generally, we can encapsulate the most important goals of this process in five clear points:

Of course, what goals an organisation achieves by implementing a DMP depends, particularly, on the efficiency and thoroughness of implementing the entire process. A correctly implemented defect detection management process can be a source of numerous benefits, but mishandling the process involves certain risks.

DMP advantages

The defect life cycle ensures that the process is uniform, standardized, predictable, and easier to manage. In addition, a well-planned and controlled defect life cycle provides a clear picture of how developers wrote the code and whether testers did their job correctly. What’s more, DMP implementation is also a source of many business benefits, prominent among them:

Saving resources and time: With DMP, you can eliminate defects during product development. Thanks to this, you avoid fixing bugs in the finished product or, even worse, having to withdraw faulty software. In addition, you save money and time for programmers who, after the end of the project, can deal with new tasks that develop the business.

Better quality: By using DMP, you will improve the quality of your products and services and minimize the number of defects. At the same time, you can guarantee your client’s timely implementation within the set budget.

Increasing customer satisfaction: The defect detection management process allows you to increase your customer’s satisfaction and positively impact their loyalty. This way, you can effectively care for your company’s reputation.

Of course, implementing defect detection management is not a cakewalk. The defect management process also poses some challenges for the company. First of all, it is a time-consuming and costly procedure. You and your team must analyze all defects on an ongoing basis, search for their causes and react to them by taking appropriate actions to eliminate them. Moreover, if you decide to implement a DMP, it’s essential to get it right. An inadequately planned defect detection management process can lead to communication problems with your suppliers and customers about the condition of the defects and generate some quality problems.

Artificial intelligence supports the DMP process

Artificial intelligence (AI) is becoming more and more present in the life of modern businesses every year and is effectively improving the actions taken by companies. Also, in the area of defect detection management, there are intelligent solutions available that you and your team can use to create better code and do it more efficiently. With AI tools available, you can spend less time creating repetitive pieces of code and focus on creating the best software.

How does it work?

As you write code, artificial intelligence trained on billions of lines of code will tell you what a function should look like or how you can complete a given line of code. These tools are called “autocomplete,” and their proper implementation allows companies to get much better results at the defect prevention stage. Tests carried out using AI in the DMP process also show that its implementation allows not only to finish work on the code faster but often allows for its finalization.

One of the most promising autocomplete solutions is GitHub Copilot, but there are more and more of these types of tools on the market; they are getting better and better, and thus they are becoming more and more popular in the development and AI community. So whether you are developing a DMP working with a new language or framework, AI tools can help you achieve results faster and better.

Use technology to achieve the desired result

The key to success lies in the right solutions that will enable you to implement DMP properly in your company. In particular, technological tools are necessary. They will allow you to manage and control the process correctly. Some companies may also need to use the support of an experienced external company in this regard, which, after getting to know the specifics of the product and the company’s activity, will be able to propose the best solutions. DMP, like any other procedure, has its lighter and darker sides, but considering the benefits of defect detection management, it is worth considering implementing this process.

About the author

Leverage AI to gain competitive advantage. Contact our expert to discuss your needs.

RECOMMENDED ARTICLES