ASPICE 3.1 vs 4.0: challenges and opportunities

Automotive SPICE (ASPICE) is a framework designed to evaluate and improve processes in automotive software and systems engineering. With the release of version 4.0, the framework has undergone significant updates to address the evolving needs of the automotive industry.

Scope expansion of Automotive SPICE

ASPICE 4.0 broadens its scope to better cover the entire mechatronic development process. This includes integrating process models for hardware engineering and machine learning engineering, areas that were not comprehensively addressed in ASPICE 3.1. Wider coverage ensures that ASPICE can support the development of complex, integrated systems that are essential in modern automotive projects. Imagine an electric vehicle where software controls everything from battery management to autonomous driving—ASPICE 4.0 is designed to ensure all these integrated systems work seamlessly together.

Maturity models

The updated maturity models in Automotive SPICE 4.0 provide more detailed and precise assessments of process capabilities. Significant changes in GP 2.1.1 strategies and alignment with international standards aim to enhance assessment consistency and applicability. For instance, if you’re developing a new infotainment system, the updated maturity models help ensure that every stage of development, from initial design to final implementation, meets rigorous quality standards.

Safety management

Safety management has become a focal point in ASPICE 4.0. The new version mandates a more detailed approach to safety and cybersecurity management throughout the product lifecycle. While ASPICE 3.1 included general safety guidelines, the newer version introduces more stringent requirements and practices, highlighting the growing importance of these areas. Consider the safety-critical systems in a self-driving car—ASPICE 4.0 ensures that every component, from the sensors to the decision-making algorithms, adheres to the highest safety standards.

Download our Guidebook to ASPICE

Get the ebookProcess detail

One of the key improvements in ASPICE 4.0 is the increased detail in process descriptions and project roles. This allows for more accurate audits and assessments, contributing to higher-quality end products. ASPICE 3.1 provided more general guidelines, which sometimes fell short in enabling precise process evaluation. For example, a team developing a new braking system can now follow clearer, more detailed guidelines, ensuring that each step of the process is thoroughly checked and verified.

ASPICE 4.0: critical and breakthrough changes

From our perspective

As providers of advanced technological solutions, ASPICE 4.0 is essential for enhancing the quality and safety standards of our products. With more detailed guidelines and better integration with other standards, we can offer our clients solutions that meet the highest requirements of the automotive market. Imagine working on cutting-edge projects like smart mobility infrastructure—ASPICE 4.0 helps us ensure that our contributions are safe, reliable, and up to global standards.

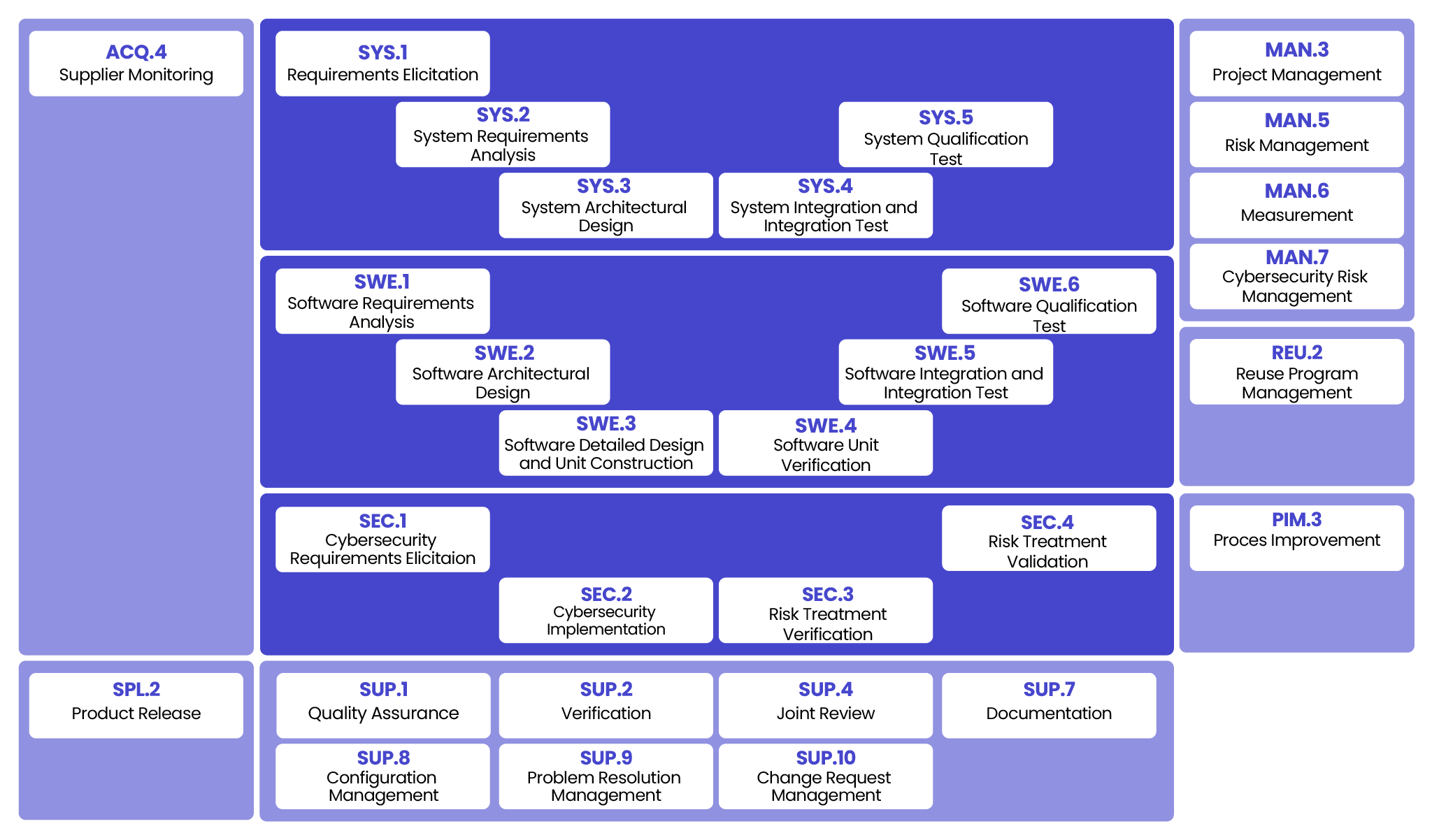

Additionally, ASPICE 4.0 introduces changes such as the modification of SYS.5 to focus on verification. This shift highlights the importance of comprehensive verification processes in ensuring product quality and reliability. As a result, our testing procedures will be expanded to include new testing methods. These enhanced testing protocols will allow us to identify and address potential issues more effectively, leading to more robust and reliable automotive solutions.

By adopting these advanced testing methods, we can ensure that our products not only meet but exceed the stringent requirements set by ASPICE 4.0, ultimately delivering higher value and safety to our clients and end users.

ASPICE V MODEL

From the users’ perspective

For end users, the introduction of ASPICE 4.0 means improved safety and reliability of automotive products. The increased focus on risk management and cybersecurity results in safer and more technologically advanced vehicles, crucial in an era of growing automation and connectivity.

ASPICE 4.0: OEM reactions and expectations

OEMs (Original Equipment Manufacturers) have responded positively to the introduction of ASPICE 4.0, viewing it as a tool to improve product quality and safety. They expect the new standard to facilitate better project management, enhance process transparency, and ensure compliance with international norms. For OEMs, ASPICE 4.0’s support for more efficient technology integration and risk management is critical in boosting consumer confidence in end products. Think about the next generation of hybrid or electric vehicles—OEMs can rely on ASPICE 4.0 to streamline development and ensure top-notch quality and safety.

Actionable insights

Implementing ASPICE 4.0 effectively involves several practical steps. First, investing in comprehensive training for your team is crucial. Workshops, online courses, and certifications can help your team grasp the new standards thoroughly. Conducting a gap analysis is also essential to identify areas where current processes fall short of ASPICE 4.0 requirements, allowing for prioritised changes and resource allocation. Utilising tools and software to automate parts of the compliance process can reduce manual workload, make operations more agile, and minimise errors. Engaging all relevant stakeholders early in the process ensures that everyone understands the benefits and requirements of ASPICE 4.0, fostering support and smoother implementation. Adopting a mindset of continuous improvement is vital—regularly review and update processes to not only meet ASPICE 4.0 standards but also to enhance efficiency and quality over time. Finally, ensure that your implementation aligns with other standards and regulations your organisation follows, such as ISO 26262 for functional safety and ISO/SAE 21434 for cybersecurity.

Real-world example: Autonomous Delivery Vehicles

Consider the development of autonomous delivery vehicles, which are becoming increasingly popular for last-mile logistics. These vehicles must navigate complex urban environments, avoid obstacles, and ensure the safe delivery of goods without human intervention. Implementing ASPICE 4.0 in such a project involves several key steps:

1. Scope Expansion: The project team can use ASPICE 4.0 to integrate both software and hardware development processes, ensuring that sensors, navigation algorithms, and mechanical systems work harmoniously.

2. Maturity Models: The updated maturity models provide a more structured approach for assessing and improving process capabilities, enabling the team to ensure consistency and high standards throughout the development of the vehicle’s autonomous systems, from initial design to final production.

3. Safety Management: Given the safety-critical nature of autonomous driving, ASPICE 4.0’s stringent safety and cybersecurity requirements ensure that the vehicle can safely handle various scenarios, including unexpected obstacles and cybersecurity threats.

4. Process Detail: Detailed process descriptions and roles help the team maintain high standards throughout development, with regular audits and assessments to catch and resolve issues early.

By adhering to ASPICE 4.0, the development team can create a reliable, safe, and efficient autonomous delivery vehicle, setting a high standard for the industry and building consumer trust.

Summary and challenges

Although implementing ASPICE 4.0 may seem costly, challenging, and time-consuming, the benefits of maintaining high quality far outweigh the potential costs. The challenges include financial and resource investments, the need for personnel training, system integration, and meeting customer expectations. These challenges, though demanding, are essential for achieving higher standards of quality and safety in the automotive industry.

Want to get a better understanding of ASPICE? Take a look at our comprehensive guide to Automotive SPICE and get access to expert knowledge.

About the author

Contact us